elcom

Belt conveyor TB50

In manufacturing and production facilities, belt conveyors are commonly employed in assembly line operations. They transport components, parts, or products between workstations or stages of the production process, allowing for efficient and continuous manufacturing operations. Belt conveyors TB 50 can be designed to accommodate different assembly line layouts, including straight, or inclined paths. They offer a wide range of belt (width, material) and drive settings (direct, remote or intermediate) depending of the flow speed, product to be transported, and work environment.

Robust structure and accessories in anodized aluminum

The TB 50 conveyor has a solid structure that guarantees its stability and durability. Made with high quality materials, this conveyor is equipped with anodized aluminum accessories. This feature gives the conveyor superior resistance to corrosion and impact, making it an ideal choice for demanding industrial environments. Thanks to its rigid structure, the TB 50 is capable of supporting heavy loads and resisting the stresses of daily transport.

Toothed belt transmission for optimal performance

The toothed belt transmission of the TB 50 conveyor is a key element of its reliability and efficiency. This cutting-edge technology allows powerful and regular traction of the belt, thus ensuring smooth movement of the transported products. The toothed belt also provides superior grip, reducing the risk of belt slippage or misalignment. Thanks to this efficient transmission, the TB 50 can handle a variety of loads and materials, providing flexibility tailored to the specific needs of each company.

Versatility and adaptability to meet all requirements

The TB 50 belt conveyor also stands out for its versatility and adaptability. Thanks to its modular design, it can be configured according to the specific needs of each application. Whether transporting light or heavy products, the TB 50 can be adjusted in terms of length, width and inclination to suit different working conditions. This flexibility allows companies to optimize their production chain and benefit from a tailor-made transport solution.

Characteristics of the TB 50 belt conveyor

The TB 50 belt conveyor is equipped with advanced technical features which give it exceptional performance in the field of industrial transport. Here are the main technical specifications of this conveyor:

- Cleanliness and durability of the stainless steel sliding base

- Robust and compact anodized aluminum accessories

- Precision of the drive roller Ø50 in anodized aluminium

- Silence and reliability of the toothed belt transmission

- Belt width : 70,100,150,150,200,300,400,500,600 mm / Max. overall length: 6000 mm (beyond that, please contact us).

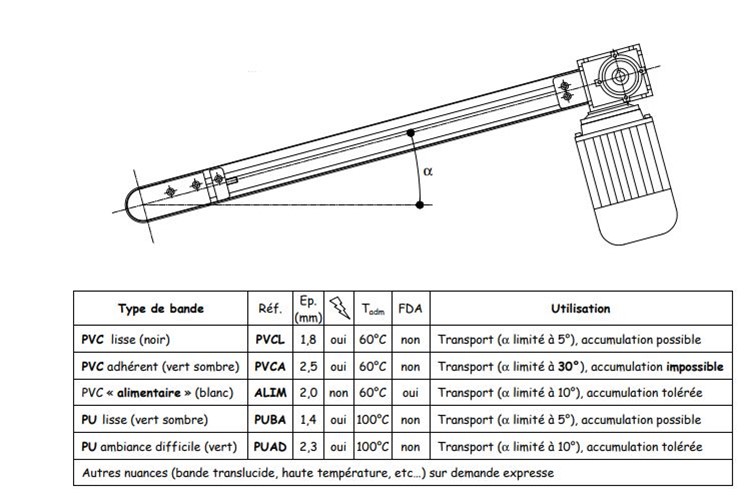

- Type of belts : smooth PVC, or adherent PVC, food PVC smooth PU, PU difficult environment, other types on request

- Accuracy and stability of the tension and alignment adjustment of the conveyor belt

- Rigidity of the structure in 40×50 anodized aluminium profile (8 mm groove for square nuts 13 mm)

- Wide range of speeds available, three-phase geared motor (90 w or 180 w 230/400 v)

- Load capacity from 40 to 100 kg depending on width.

- Speed and inclination : please contact us

- Drive : direct / remote or intermediate

In addition to these technical characteristics, the TB 50 belt conveyor stands out for its quiet operation. In addition, its Ø50 anodized aluminum roller drive ensures increased precision when moving the transported products. These additional benefits make the TB 50 an ideal choice for work environments where quietness and precision are essential.

In summary, the TB 50 belt conveyor offers varied belt widths, belt types suitable for different needs, flexible speeds and allowable loads, as well as drive options and maximum length adapted to the specifications of each application . With its silent operation and its precise drive by Ø50 anodized aluminum roller, the TB 50 represents an efficient and reliable solution for the transport of products in various industries.

Articulated conveyor TB 50

The TB 50 conveyor offers a range of versions to meet the specific needs of each application, including the articulated version. This articulated version of the TB 50 has distinct features that make it a versatile solution for transporting products in various industrial environments. Here are the details of the characteristics of the TB 50 articulated conveyor

- Belt width: The articulated TB 50 is available with different belt widths, ranging from 70 mm to 500 mm. This variety of widths allows a wide range of products of different sizes and shapes to be transported, providing great flexibility in industrial applications.

- Maximum length: The articulated version of the TB 50 has a maximum length of 4000 mm. This length provides extended reach for transporting products over greater distances, while allowing optimal integration into existing facilities.

- Maximum speed: The articulated TB 50 is capable of reaching a maximum speed of 48 m/min. This speed allows rapid and efficient movement of transported products, thus contributing to an increase in productivity and optimization of logistics and handling processes.

- Entraînement : Comme les autres versions du TB 50, la version articulée offre des options d’entraînement direct, déporté ou intermédiaire. Cela permet une flexibilité dans le positionnement de l’entraînement en fonction des besoins spécifiques de chaque application, assurant ainsi une performance optimale du convoyeur.

The articulated version of the TB 50 offers a suitable solution for applications where flexibility and adaptability are essential. Whether for transporting light or heavy loads, this version of the TB 50 can be adjusted to meet the specific requirements of each industry.

conveyor TB 50 drum motor

It is possible to provide you with a TB 50 drum motor version:

The TB 50 drum motor version is a specific variation of the conveyor which offers unique characteristics to meet the transport needs in various industrial applications

Technical details

Belt width: The TB 50 drum motor is available with specific belt widths of 290 mm, 390 mm and 490 mm. These different width options help accommodate a variety of products of different sizes and shapes, providing flexibility in conveyor selection based on specific needs.

Maximum length: The TB 50 drum motor version has a maximum length of 2000 mm. This length makes it possible to efficiently transport products over medium distances, while offering easy integration into existing installations.

Maximum speed: The TB 50 drum motor can reach a maximum speed of 48 m/min. This speed allows rapid and efficient movement of transported products, thus contributing to an increase in productivity and optimization of logistics and handling processes.

Drive: Unlike other versions of the TB 50, the drum motor version uses a drum motor drive. The drum motor is a component integrated into the conveyor structure, which combines the function of drum and motor in a single element. This allows for compact and simplified operation of the conveyor, making it easier to install and use.

The TB 50 drum motor version offers an efficient and practical solution for transporting products in various industrial environments. Thanks to its specific belt width, its maximum length of 2000 mm, its maximum speed of 48 m/min and its drum motor drive, this conveyor is suitable for applications requiring reliable and precise transport.

Additional accessories for the conveyor

The TB 50 conveyor offers a range of optional accessories which improve its functionality and meet the specific needs of each application. Here are the details of the accessories available for the TB 50 conveyor:

Standardized leg: Standardized legs are feet that can be added to the TB 50 conveyor to ensure its stability and optimal height. These legs provide solid support for the conveyor, allowing it to operate reliably and securely.

Aluminum profiles: Aluminum profiles are additional elements that can be attached to the TB 50 conveyor. These profiles provide additional structure and can be used for specific applications such as mounting sensors, guides or other accessories.

Support roller kit: The support roller kit includes additional rollers that can be installed on the TB 50 conveyor. These rollers provide additional support to the products being transported, ensuring smooth and regular movement on the conveyor belt.

Side guide: The side guide is an accessory that helps guide products as they are transported on the TB 50 conveyor. It ensures precise and stable positioning of the products, thus avoiding any slippage or misalignment during transport.

PE/Stainless steel guide profile: The PE/Stainless steel guide profile is a specific accessory for guiding products on the TB 50 conveyor. It offers a smooth, wear-resistant surface for optimal contact with the products, thus reducing friction and possible damage.

Knife edge kit: The knife edge kit is used to facilitate the transfer of products from the TB 50 conveyor to other equipment or processing areas. It allows precise and secure transfer of products, thus minimizing the risk of damage or blockage.

Groove Nut: The groove nut is a fastener that fits the TB 50 conveyor profiles. It allows other accessories or components to be easily attached to the conveyor profiles, providing flexibility for adding or the subsequent modification of additional elements.

These accessories improve the functionality and adaptability of the TB 50 conveyor by meeting the specific needs of each company. Whether to ensure stability, precise product guidance or attach additional elements, these accessories help optimize conveyor efficiency and performance in various industrial applications.

Video of belt conveyor TB50

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.