elcom

Belt conveyor TB90

The TB90 belt conveyor is a versatile industrial solution that provides numerous benefits in various industries. Thanks to its specific characteristics, it responds to various transport and product delivery issues.

Function and use of the TB 90 belt conveyor

The TB90 belt conveyor is designed to efficiently move products from point A to point B in production and material handling processes. Its use helps optimize production lines, improve efficiency and reduce handling costs.

Main properties

- Cleanliness and durability of the stainless steel sliding base

- Robustness and compactness of anodized aluminum accessories

- Wide range of speeds available for the SEW geared motor (120W, 180W or 250W, 230/240W) three-phase

- Precision of the drive by Ø90 steel roller

- Belt width: 100, 150, 150, 200, 300, 300, 400, 500, 600, 600, 800, 1000, 1200 mm / overall length: 6000 mm (beyond, consult us).

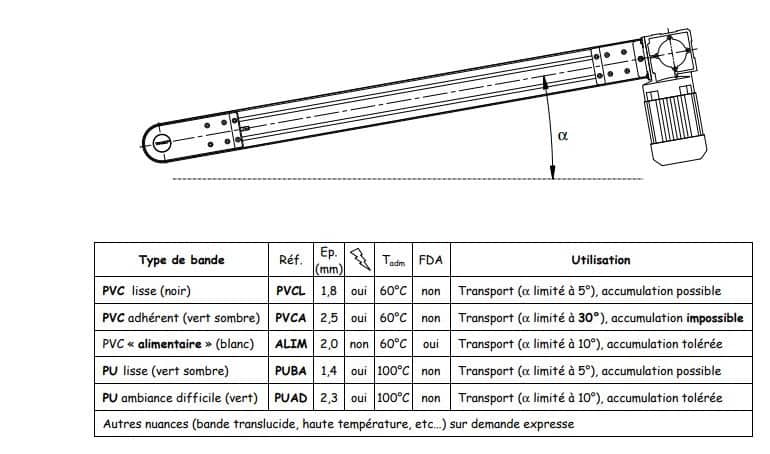

- Type of belts: smooth or adherent PVC, food PVC, smooth PU, difficult environment PU, other types on request.

- Accuracy and stability of the tension and alignment adjustment of the conveyor belt

- Rigidity of the 85×40 anodized aluminium profile structure (8mm grooves for 13mm square nuts)

- Load capacity from 100 to 200 kg depending on width.

- Speed and inclination: please contact us

- Drive: direct or remote

The use of the TB90 belt conveyor brings many advantages to industries. It improves the efficiency of production processes, optimizes the management of handling lines, ensures precise and reliable transport of products, and helps maintain high standards in terms of hygiene and cleanliness.

Characteristics of the TB 90 drum motor

- Belt widths : 500 /600 /700 /800 /1000

- length : 4000 mm

- speed : 14m/min

- Drive : drum motor

Accessories for the TB90 conveyor

The TB90 conveyor can be equipped with a range of accessories that enhance its functionality and meet the specific needs of each application. Here are some of the accessories available:

Leg: The legs allow you to place feet on the conveyor, thus ensuring its stability and correct alignment. They also facilitate the installation of the conveyor in the production environment.

Support roller kit: This kit includes additional support rollers which reinforce the conveyor and better support the transported load. It improves the stability of the conveyor and guarantees regular delivery of products.

Side guide: The side guide is a guiding device installed along the conveyor to hold products in position while they are moving. It ensures precise alignment and prevents deviations or unwanted movement of products, ensuring efficient and secure transportation.

PE/Stainless steel guide profile: This profile guide device is used to direct the products on the conveyor. Available in materials such as polyethylene (PE) or stainless steel (Inox), it provides a smooth, wear-resistant surface, facilitating product movement and minimizing unwanted friction.

Groove nut: This accessory allows the TB90 conveyor to be connected to other structures or equipment present in the production environment. It provides a strong and secure connection, ensuring seamless integration of the conveyor with other elements of the production line.

These accessories help improve the performance and efficiency of the TB90 conveyor by providing additional features such as stability, precise product guidance and the possibility of integration with other equipment. They make it possible to adapt the conveyor to the specific needs of each application, thus optimizing the production flow and guaranteeing reliable and smooth transport of products.

Video of belt conveyor TB90

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.