Elcom

Industrial goods manufacturing

To transport industrial goods, the main technology uses is linear transfers or conveyors. In addition, workstations and Kanban cabinets are also very much in demand for the manufacture of industrial goods. As safety remains crucial, aluminium carterizations are commonly designed.

What equipment is used for manufacturing?

To transport industrial goods, industries mainly use linear transfers for bearings, for example. Conveyors and workstations are also very much in demand.

In the manufacture of industrial goods, in addition to conveyors, industries often use other equipment and systems for transporting and handling products.

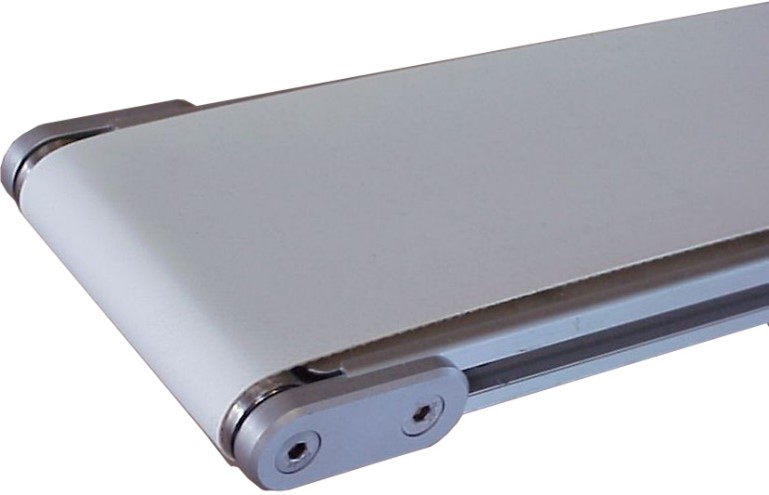

Linear transfer

Linear transfers are mechanisms that enable the precise linear movement of products from one workstation to another. They are often used in production lines for operations such as assembly, inspection and processing. Ball bearings are incorporated into these systems to reduce friction and facilitate linear movement.

Accumulating conveyor systems

These conveyor systems enable products to be temporarily accumulated at a specific point on the production line. This makes it possible to manage variations in speed between different stages of the process without interrupting production.

Ergonomic workstations

Workstations are designed to enable operators to work efficiently while maintaining their comfort and safety. They are height-adjustable, offer appropriate lighting and are equipped with ergonomic features to reduce worker fatigue.

Accumulation conveyor systems

These Faber conveyor systems allow products to be temporarily accumulated at a specific point on the production line using plastic screws. This makes it possible to manage speed variations between different stages of the process without interrupting production.

In short, the manufacture of industrial goods relies on a variety of transport and handling solutions, from conveyors and industrial robots to rotary tables and ergonomic workstations. These equipment and systems are carefully designed to meet the specific needs of each production process, guaranteeing efficiency, precision and safety throughout the production chain.

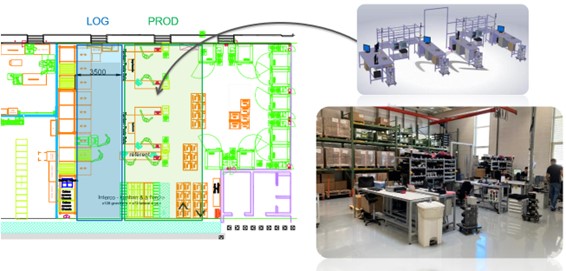

Case study

Project :

On March 20, the decision was made for a very important customer in the manufacturing of industrial goods to replace the assembly stations of the 6x Bays (during the re-reaction of the ESD resin during the summer shift)

On August 22, with the new configuration we restarted production as if nothing had happened.

Solution

For this project, we accomplished a series of key milestones in just 5 months, thanks to strong collaboration and meticulous execution. First, we worked closely with users to understand their specific needs, allowing us to direct our efforts in a targeted manner.

The solution is divided into several stages, which give rise to the implementation and completion of the project. Once the needs were identified, we validated the new configuration, thus ensuring that our approach was in perfect harmony with the objectives of the project. . To seamlessly integrate electrical tooling, we conducted an in-depth study to optimize its integration into our existing process.

In the interest of increased efficiency, we quickly established a quote and proceeded to order the Elcom workbenches, thus guaranteeing judicious management of resources and deadlines.

We also took care of the unloading of existing workstations to free up the space needed for the new configuration. The meticulous transfer of tooling from the old stations to the new ones went smoothly, minimizing potential disruption.

To ensure optimal electrical infrastructure, we undertook a complete rewiring of the area. Additionally, we have reorganized Kanbans to improve the management of our workflows.

Finally, in strict compliance with the set deadlines, we managed to reinstall and restart all workstations impeccably, ensuring a smooth transition to our new configuration. These achievements demonstrate our collective dedication and our ability to carry out this project efficiently, thus meeting needs and expectations in an exemplary manner.

They trust us

Stäubli

Michelin

Schneider Electric

Groupe SEB

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.