Elcom

Aerospace

The aeronautics industry and elcom, a long history of collaboration.

The aerospace sector has always been a cutting-edge industry, and the entities of the hellomoov’ ecosystem have always supported it.

Our geographical locations enable us to be a privileged partner for the specific problems of the aeronautics industry.

The wide range of elcom products naturally finds its place in such diverse environments as assembly workshops, test areas and control laboratories.

Aeronautics at Elcom in detail

Our in-depth knowledge of our products enables us to work with industry players on more complex projects, and to design high-performance industrial assemblies to offer you the most appropriate choices.

Our gangways enable technicians to work at height in complete safety.

What’s more, reconfiguration is always possible in situ.

Finally, we’ll continue to follow developments in this sector, which is constantly reinventing itself and pushing us to be a little better every day.

As for the future, it’s not a question of foreseeing it, but of making it possible (Antoine de St Exupéry).

Case study in aeronautics

Project

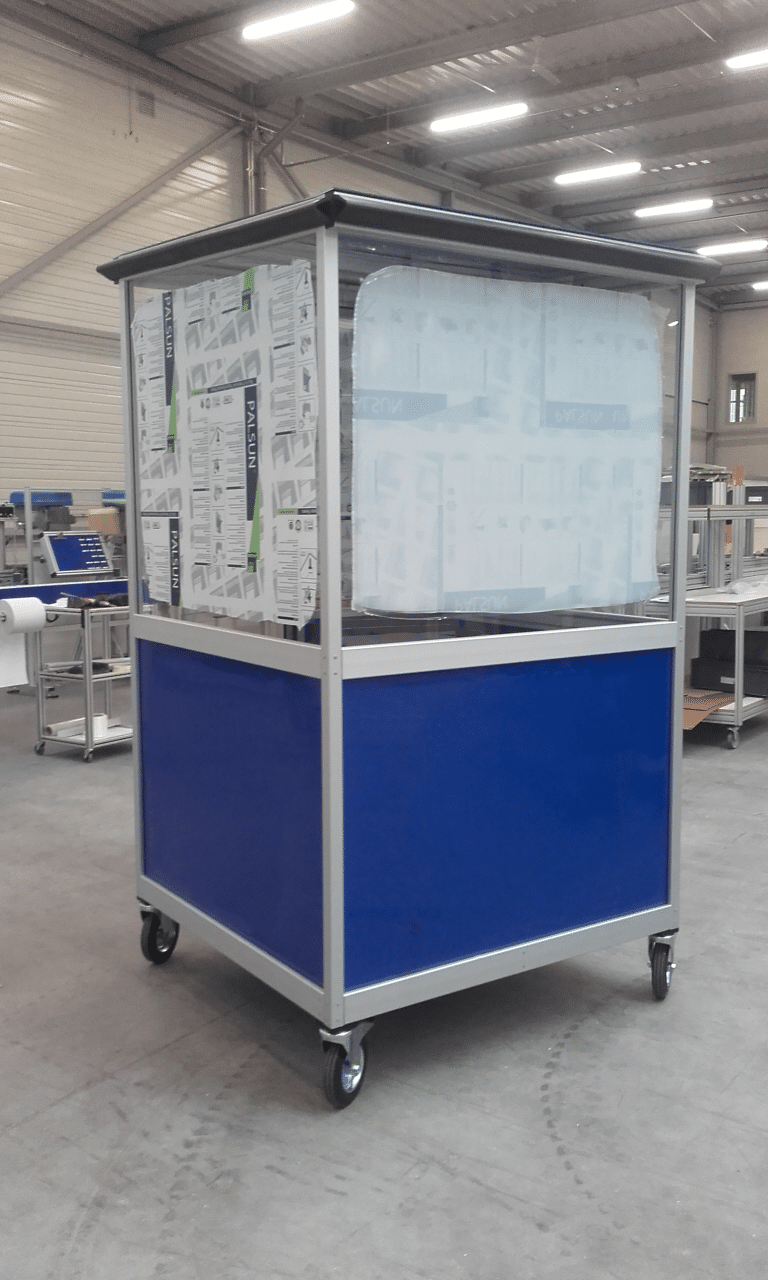

Our client, a major player in the aeronautics industry, had the project of setting up cabins that could move easily on the airport tarmac but also capable of withstanding bad weather in order to store signage without the slightest problem.

Solution

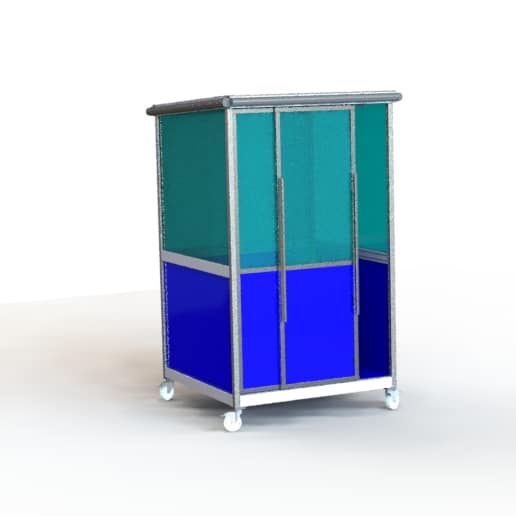

To respond to and carry out our client’s project, we have developed cabins specially designed for use on the airport tarmac. These cabins come with unique features that make them perfectly fit for purpose.

First of all, mobility is one of the essential aspects of these cabins. They are equipped with sturdy wheels that allow easy and smooth movement on tarmac. This ensures great flexibility when positioning cabins to store or deploy traffic signs, wherever they are needed.

When it comes to weather resistance, our cabins are designed to cope with the most extreme environmental conditions. They are built with durable, weather-resistant materials

The cabins are built on casters in smooth-sided profiles and with a sealing system specially made for outdoor use.

Stäubli

Michelin

Schneider Electric

Groupe SEB

What kind of equipement are used in the aerospace industry ?

In aeronautics, different equipment is used in assembly workshops, test areas, gateways and control laboratories to build, test and maintain aircraft:

Assembly shops/workstations: Assembly shops are spaces where the different parts of the aircraft are manufactured and assembled to form the complete structure.

Testing Laboratories: Testing laboratories are facilities where parts and materials used in the construction of aircraft are subjected to extensive testing to ensure compliance with safety and quality standards

Catwalks used in the aviation industry are structures specially designed to allow technicians to work at height safely during aircraft servicing, repair and maintenance operations. These walkways are usually made from aluminum profiles, making them both sturdy and lightweight.

What are the standards in the aerospace industry ?

Aeronautics is a highly regulated and secure field, where standards play an essential role in ensuring flight safety and the quality of products and services. Here is an overview of the main standards that govern aeronautics:

Compliance with ISO 9001-2008 quality

A very important point for a supplier in the aeronautical sector is quality management.

ISO 9001-2008 is an international standard relating to quality management system. Although it was replaced in 2015 by ISO 9001-2015, some organizations and companies in the aviation sector can still comply with the earlier version.

This standard aims to help companies implement an effective quality management system and continuously improve their performance. In aeronautics, it is essential for companies to maintain a high level of quality, because flight safety and product reliability are critical issues.

ISO 9001-2008 sets out requirements for quality management systems for organizations seeking to demonstrate their ability to consistently provide products and services that meet customer requirements and applicable regulations. The ultimate goal is to increase customer satisfaction through continuous improvement of processes and quality.

Objectives of the ISO 9001-2008 standard

Modular aluminium for aerospace

The modularity of equipment made from aluminium sections is a key advantage in many industries, including aerospace. Modularity refers to the ability to easily assemble, disassemble and rearrange parts and components to create different configurations or structures to suit specific needs.

Equipment made from aluminium profiles offers several advantages in terms of modularity:

– Design flexibility: Aluminium profiles are available in a variety of standardised shapes and sizes, enabling customised equipment or structures to be designed to meet specific needs. Manufacturers can easily assemble profiles to the dimensions required to meet unique project requirements.

– Easy assembly and disassembly: Aluminium profiles are often designed with quick and simple connection systems, such as screws, bolts or snap-on connectors. This makes it easy to assemble and disassemble equipment, enabling it to be moved or reorganised quickly.

– Scalability: The modularity of aluminium profile equipment means that components can easily be added or removed, making it scalable to meet changing needs. This offers great flexibility in adapting to new requirements, design changes or technological developments.

– Easy transport and storage: Modular aluminium parts are often lightweight, making them easy to transport and store. By dismantling them partially or completely, equipment can be packed compactly to save space when not in use.

– Reuse of components: In some cases, modular equipment can be dismantled and the aluminium sections reused to build new equipment or structures. This maximises the use of materials and reduces waste.

In the aerospace industry, the modularity of aluminium section equipment is used in a number of areas, including

- Design of modular walkways and scaffolding to facilitate access to different parts of the aircraft during servicing and maintenance.

- Construction of height-adjustable workstations, enabling technicians to work on different parts of the aircraft depending on its dimensions.

- Manufacture of modular handling and storage trolleys for the efficient transport and management of aircraft parts and components.

- Creation of modular structures for inspection laboratories, enabling the space to be easily reconfigured to meet specific testing and inspection requirements.

Lean manufacturing

In the aerospace industry, Lean Manufacturing is applied to improve productivity, quality, safety and profitability throughout the aircraft life cycle, from design to production, assembly, testing and maintenance.

Our experts are here to answer your questions, support you, and guide you through all your projects.