elcom

Heavy duty pallet transfer system TM

TM monorail transfer system has been designed for heavy duty working areas, and suited for moving heavy parts (up to 300 kgs)

lts compact overall dimensions and the optimal ergonomics provided by the system facilitate the arrangement of the working place

Usefulness of linear shuttle transfers

The main objective of linear shuttle transfers is to ensure smooth and precise movement of products from one workstation to another, following a predefined route. They are often used in production lines where different operations must be performed on parts to assemble, machine, test or inspect them. By transporting products from one station to another in an automated manner, linear shuttle transfers help reduce downtime and optimize production flows.

These transfers are particularly suitable for the production of complex parts, because they offer the possibility of applying several manipulations to the same product. This allows multiple operations to be performed on the same part without having to move it manually, improving the efficiency and precision of the production process.

In addition to facilitating product transportation, linear shuttle transfers offer several specific features and advantages. They are usually equipped with accumulation chain technology, which allows the shuttle to move smoothly along the defined path. This technology guarantees smooth and stable movement of the shuttle , reducing the risk of blockage or malfunction.

TM transfers are designed to allow precise change of direction of shuttle . Using lifting units and a shifting mechanism, shuttle can be moved sideways to change direction according to the needs of the production process. This offers great flexibility in terms of shuttle routing and allows adaptation to the specific requirements of each production stage.

Regarding technical characteristics, TM transfers are capable of supporting heavy loads of up to 100 kg. This makes them suitable for transporting different types of products, whether large or heavy. Additionally, TM transfer trays are configurable, meaning they can be adjusted according to the size and shape of the products to be transported. This modularity makes it possible to optimize the use of space and adapt to the specific needs of each application.

In summary, linear shuttle transfers, such as TM transfers, are essential equipment for the automated transport of products to different workstations. They are particularly suitable for the production of complex parts that require several manipulations. Their ability to ensure moderate flow, their accumulation chain technology, their precise change of direction, their ability to support heavy loads and their configurable trays make them versatile and efficient tools in industrial production processes.

Technical characteristics

The technical characteristics of the TM transfer (Single Channel Transfer) contribute to its efficiency and versatility in production processes. Here is a detailed description of each feature and its usefulness:

- Accumulation Chain Technology: Transfer TM uses accumulation chain technology for moving shuttle . This technology allows for smooth and regular movement of the shuttle along the defined path. The shuttle are placed on a chain which guides them throughout the journey, reducing the risk of blockage or malfunction. This ensures reliable and continuous transport of products from one workstation to another.

- Change of direction by shifting unit or turntable: The TM transfer is equipped with units which allow the direction of movement of the shuttles to be changed. Thanks to a shifting mechanism, the shuttle can be moved sideways to rotate in the desired direction. This feature provides great flexibility when routing shuttle across workstations, making it easy to adapt to the specific requirements of the production process.

- Tray load up to 100 kg: The TM transfer is designed to transport heavy loads. It can support loaded trays weighing up to 100 kg. This high load capacity makes it suitable for transporting various types of products, including those that are relatively heavy, such as mechanical parts or automotive components. Thus, it helps to optimize the transport of loads in industrial production processes.

- Configurable trays (max. 1m²): The TM transfer trays are configurable, which means that they can be adapted according to the size and shape of the products to be transported. The maximum surface area of the board can reach 1 square meter. This modularity makes it possible to adapt to the specific needs of each application, thus optimizing the use of space and guaranteeing precise and secure handling of products at workstations.

- Operation possible in both directions: The TM transfer is designed to allow operation in both directions. This means it can transport products in both directions, providing greater flexibility when planning operations. It can be used to move products forward and backward as needed in the production process, providing further optimization of workflows.

TM transfer accessories

In addition to these main technical characteristics, the TM transfer can be equipped with different accessories to meet the specific needs of each application. Some of the commonly used accessories include:

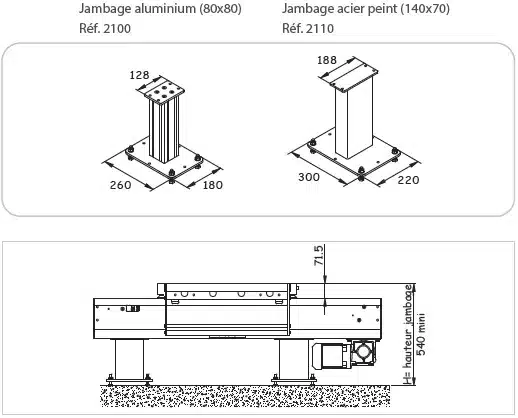

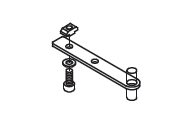

- Leg (placement of feet): The leg helps stabilize the transfer by providing it with a solid base. It is useful when the transfer must be used in specific conditions that require increased stability.

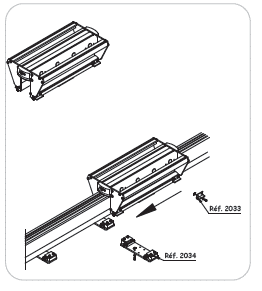

- Stopper : The stop is a device that allows the precise stopping of the shuttle at a specific location on the transfer. It is used when shuttle operations require precise and repeatable stopping.

- Detector support: The detector support is designed to receive a sensor, such as a proximity sensor or an optical sensor. It allows automatic detection or control functionalities to be integrated into the transfer process, providing further automation.

These additional accessories increase the versatility of the TM transfer by allowing the addition of specific functionalities depending on the needs of each application.

The technical characteristics of the TM transfer, such as accumulation chain technology, change of direction by shifting unit or turntable, high load capacity, configurable trays and bidirectional operation, make it a high-performance and versatile tool for automated transportation of products in industrial production processes.

Optional accessories such as the leg, the stop and the detector support allow even more precise adaptation to the specific needs of each application.

video of Transfer TM

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.