elcom

Inflatable belt conveyor

An inflatable belt conveyor, also known as an air-supported belt conveyor, is a type of conveyor system where the conveyor belt is supported and propelled by air pressure. Here are some characteristics of inflatable belt conveyors

Operation of inflatable belt conveyors

This conveyor is suitable for workpiece pallets or boxes with flat bottoms.

The line can be motor-driven or operated by hand.

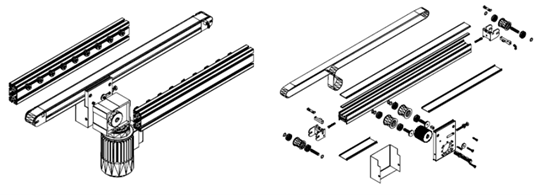

Load transfer of the weight of the product is implemented via ball bearings mounted on the aluminium profiles. The profiles simultaneously serve to guide the workpiece pallets or boxes.

These are moved forwards by a continuously-running conveyor belt whose pressure against the bottom of the workpiece pallets is controlled pneumatically. The pressure of the conveyor belt moves the workpiece pallets, which can also easily be running in accumulation mode using stoppers. Indexing units are also possible.

Advantages of a inflatable conveyor

Air-Supported Belt: The conveyor belt in an inflatable belt conveyor is supported by a cushion of air. It typically consists of a series of air chambers or compartments located beneath the belt. The air pressure within these chambers creates a floating effect that supports and propels the belt.

Reduced Friction: The air cushioning between the belt and the supporting surface reduces friction, allowing for smoother and more efficient movement of the belt. This can result in energy savings compared to traditional belt conveyors.

Variable Pressure Control: The air pressure within the inflatable chambers can be adjusted to control the stiffness and support provided to the belt. This allows for flexibility in optimizing the conveyor’s performance based on the specific requirements of the application.

Easy Installation and Flexibility: Inflatable belt conveyors are typically lightweight and modular in design, making them easy to install, dismantle, and reconfigure. They can be quickly set up or relocated as needed, offering flexibility in various industrial settings.

Quiet Operation: Compared to some other conveyor systems, inflatable belt conveyors tend to operate quietly due to reduced mechanical contact and friction.

Gentle Material Handling: The air-supported belt provides a cushioning effect, making it suitable for handling delicate or fragile materials that may be susceptible to damage or breakage on traditional conveyors.

Low Maintenance: Inflatable belt conveyors often have fewer moving parts compared to traditional conveyors, resulting in reduced maintenance requirements. However, regular inspections and maintenance of the air supply system are necessary to ensure optimal performance.

Limited Load Capacity: Inflatable belt conveyors typically have lower load capacity compared to some heavy-duty belt conveyors. They are suitable for handling lighter loads and may not be ideal for heavy bulk material transport.

technical characteristics

Inflatable belt conveyors have specific technical characteristics that contribute to their proper functioning and efficiency. Here are the main technical characteristics of these conveyors:

Toothed belt drive: Inflatable belt conveyors are equipped with a toothed belt drive system. This belt, which is usually made of durable synthetic material, ensures efficient transmission of power from the engine to the conveyor belt.

Steel pulleys mounted on ball bearings: The conveyors are equipped with robust steel pulleys. These pulleys are mounted on high quality ball bearings, which provides smooth and smooth movement of the conveyor belt.

PA belt guide: Inflatable belt conveyors are equipped with a PA (polyamide) belt guide. This guide ensures precise positioning of the conveyor belt, preventing excessive lateral movement and ensuring correct alignment along the entire length of the conveyor.

Load supported by stainless steel bearings: On each side of the conveyor, the load is supported by stainless steel bearings. These bearings provide corrosion resistance and increased durability, ensuring strong and reliable support for trays, workpiece carriers or transported boxes.

Adjusting the pressure in the inflatable system: A key feature of inflatable belt conveyors is the ability to adjust the pressure in the inflatable system. This pressure setting allows control of the thrust exerted on the platens, providing flexibility to adapt the conveyor to the specific needs of each application. It also optimizes transport stability and prevents any unwanted slippage of the load.

Thanks to these technical characteristics, inflatable belt conveyors offer high reliability, smooth movement of transported products and great flexibility to adapt to different loads and specific industry requirements.

Dimensions (mm)

Width A: 200 to 500 maximum

Length 6 m max

Accumulation possible over the entire length

Pushing force: 25 kg

Engines

230/400 v Three-phase 50 Hz

Speed (m/min.) +/- 10%: 5 – 10 – 12 – 16 – 18

Maximum pressure 0.8 bar

Pressure regulator not supplied

Video of belt conveyor

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.