Elcom

Lean solutions

Ergonomic solutions for lean manufacturing are approaches that aim to reduce waste and improve production process efficiency without relying on complex technologies or major interventions. They focus on organizational changes and continuous improvements that optimize manufacturing operations.

Examples of ergonomic solutions used in lean manufacturing

Implementation of production flow:

One of the main ideas of lean manufacturing is to create a continuous production flow without interruptions or excessive waiting times. This can be achieved by organizing machines, equipment, and workstations in a way that allows parts and products to move easily from one stage to another, thereby avoiding bottlenecks and downtime.

5S and workplace organization:

The 5S is a visual management method that aims to create a well-organized, clean, and efficient work environment. The five principles of 5S are Sort (get rid of what is unnecessary), Set in Order (organize items systematically), Shine (clean), Standardize (establish standard procedures), and Sustain (maintain the achieved results). By applying these principles, companies can reduce search times, errors, and delays.

Continuous improvement:

Lean manufacturing encourages continuous improvement by encouraging employees to identify and solve problems at the source. This can be done by implementing improvement suggestion processes, workgroups, or quality circles. The idea is to empower employees and provide them with the necessary tools to identify problems, propose solutions, and implement improvements.

Reduction of stocks:

Another passive approach in lean manufacturing is to reduce inventory levels. Excessive stocks are considered waste because they take up space, require management costs, and can hide quality or production flow issues. By adopting techniques such as Just-In-Time production, companies can reduce inventory levels while maintaining a regular production flow.

Standardization of procedures

Standardizing procedures is essential for improving efficiency and reducing errors. By establishing clear standard work procedures, companies can minimize variations and quality deviations while facilitating employee training and skills transfer.

Workload balancing

Balancing workloads involves fairly distributing tasks and responsibilities among employees. This helps reduce bottlenecks and avoid work overload, which can lead to delays and a decrease in quality.

These ergonomic solutions all contribute to optimizing manufacturing processes, reducing costs, improving quality, and satisfying customers within the framework of lean manufacturing.

Supply Systems

Supply systems play a crucial role in the efficient management of stocks and product flows. To ensure that products are available at the right time, in sufficient quantities, and with adequate quality, many companies adopt the “just-in-time” (or “just in time”) strategy. The main objective of this approach is to minimize inventory levels and avoid production fluctuations and product losses.

In this context, elcom offers an extensive range of customizable modules to help optimize your supply systems. Two types of modular furniture stand out particularly to support your efforts: dynamic supply racks and carts.

Dynamic supply racks offer a practical solution for product storage and handling. These racks are designed to allow easy and quick access to items, facilitating flow management and reducing the time needed to pick products. By using these racks, you can optimize storage space and improve the overall efficiency of your supply system.

Carts are also essential elements to facilitate product provisioning and transport. They are designed to be versatile and suitable for different logistical tasks. Carts can be equipped with various h’ 8 40 accessories specially developed to meet your specific needs. These accessories are designed to simplify the setup and use of the carts, thus enhancing the efficiency and productivity of your supply operations.

By combining these customizable modules, such as dynamic supply racks, carts, and h’ 8 40 accessories, you can create an efficient supply system tailored to your specific requirements. This allows you to maximize the use of storage space, optimize product flows, and minimize costs associated with inventory management.

APPLICATIONS FOR SUPPLY SYSTEMS

Dynamic supply racks are often modular structures designed to bring the necessary components closer to operators or production lines. They play a key role in pull flow systems, where they are supplied during a Milk Run tour with Kanban management.

In the specific context of supply systems, elcom offers a combination of its h’8 40 D30 range with h’8 40 profiles in 40×40 dimensions. This combination allows for a blend of modularity and strength, aiming to provide optimal comfort and improve the durability of your frames.

The D30 range offers remarkable modularity, meaning it can be adjusted and customized to meet your specific supply needs. The h’8 40 profiles in 40×40 dimensions ensure a sturdy and robust structure for the frames, ensuring their durability and resistance in demanding work environments.

By using this combination of range and profiles, you can create dynamic supply racks tailored to your production processes and specific requirements. These racks will allow you to bring the necessary components closer to your operators or production lines, thus improving the efficiency and productivity of your supply system.

Carts play an essential role in implementing the concept of the Tugger trains, which is often used in supply systems. They are the physical equipment that enables the Milk Run tour. These carts form a convoy pulled by a towing vehicle and are used for transporting the necessary components.

In the context of the Tugger trains, carts are used to deliver components to different workstations. At each station, the “milkman” unloads the relevant components and loads the containers with components that have been consumed or used. This ensures a continuous flow of materials and components needed for production, avoiding waiting times and interruptions.

Carts are designed to facilitate loading, unloading, and movement of components. They can be equipped with various accessories specifically tailored to the needs of your supply system. These h’8 40 accessories developed by elcom simplify the setup and use of carts, thus enhancing the efficiency and productivity of your supply operations.

By using carts in your supply system, you can optimize the transportation of components and ensure a regular and efficient supply. The concept of the tugger train with carts pulled by a towing vehicle establishes a smooth and coordinated method for delivering the necessary components to different production stages.

Line-side Equipment - ERGO Mobile

At elcom, we offer a range of line-side equipment called ERGO Mobile, which has been specifically designed to meet the varied needs of businesses. Four models of ERGO Mobile have been developed and optimized to satisfy different types of usage.

ERGO Mobile L is the ideal complement to customized workstations. It allows bringing the necessary materials closer to employees, thus promoting quick and ergonomic access to materials. This model is designed to facilitate the handling of tools and components, thereby improving the efficiency of line-side operations.

ERGO Mobile T is equipped with central spacers that allow access to shelves and bins from both sides of the cart. This offers the possibility of positioning tools and materials between two workstations, facilitating resource sharing and collaboration between operators.

ERGO Mobile U is specially designed for safely transporting heavy loads. This model is equipped with four sturdy spacers, just above the wheels, which prevents the cart from tipping and provides good support for the shelves. It offers a robust and reliable solution for transporting heavier materials.

ERGO Mobile S is ideal for transporting small quantities of products. This model is height-adjustable, allowing it to be adapted to the specific needs of your company. Additionally, the shelf’s perimeter retains the parts, thus preventing falls or losses during transport.

These ERGO Mobile line-side equipment are designed to improve efficiency, flexibility, and ergonomics in line-side operations. They offer solutions tailored to various needs, whether it’s bringing the necessary materials closer to employees, facilitating resource sharing between workstations, safely transporting heavy loads, or managing the transport of small quantities of products.

In summary, elcom’s ERGO Mobile line-side equipment is available in several models to meet your company’s specific needs. Whether it’s ERGO Mobile L, T, U, or S, these equipment offer practical, ergonomic, and secure solutions to enhance line-side operations, thereby improving your company’s efficiency and productivity.

To ensure effective organization, flexibility is essential. The new ERGO Mobile elements embody this characteristic precisely. They combine low self-weight with a high load capacity, all with an optimized chassis. Thanks to these features, it becomes possible to quickly transport materials and parts to the right places. Moreover, these carts are customized, allowing them to be adapted to each work phase, making production faster and more flexible.

Manual or Gravity Conveyor Systems

Manual or gravity conveyor systems are used for the movement of goods, products, or materials in a workspace. They facilitate the efficient transport of loads from one point to another, often without requiring additional electrical or mechanical energy.

Manual conveying refers to the use of human force to move goods. It can involve carrying objects by hand, pushing carts or dollies, or using equipment such as manual pallet trucks to move pallets or gravity conveyors.

Gravity conveying harnesses gravity to move goods. This type of system utilizes slopes or inclines in the facilities to allow objects to move by gravity. Loads are usually placed on trays or chutes that are inclined downward. Due to the slope, objects naturally move downward without the need for motors or external power.

Manual or gravity conveyor systems offer several advantages. They are generally easy to set up, cost-effective, and require minimal complex maintenance. They are also flexible and can be adapted to different types of loads or products. Additionally, they can help reduce fatigue and the risk of injuries to workers, as manual handling is facilitated or physical effort is reduced thanks to gravity.

However, it is important to note that these systems may have limitations in terms of load capacity and speed of movement. They are generally better suited for work environments where transport volumes are relatively low to moderate and where speed is not a critical factor.

MOOV module connection accessories provide a simple and effective solution for moving your products between workstations or from kanban shelves. Their use helps reduce the physical effort required from your employees, thus minimizing the risk of Musculoskeletal Disorders (MSDs) while increasing your team’s productivity.

Elcom offers three categories of assembled mechanical industrial solutions, which allow you to implement these MOOV module connections and address the different constraints you may encounter. These solutions provide the necessary flexibility to optimize your work processes and improve the efficiency of your supply chain.

ROLLER CARRIERS

Roller carriers are a version of conveyors used to ensure supply from kanban shelves. They offer a flexible solution for workstation groups and manufacturing cells, integrating control procedures, various processes, and high productivity.

These roller carriers allow fast transport of parts and materials, contributing to overall productivity increase. Moreover, by using these conveyors, users are relieved from unnecessary lifting tasks. Thanks to the close integration of work tables with the transport paths, a more homogeneous material flow is favoured.

Roller carriers offer several advantages in the supply processes. They enable smooth and regular movement of parts, thus reducing interruptions and delays. Additionally, they facilitate loading and unloading of parts onto kanban shelves, making the process more efficient.

The design of Roller carriers can vary according to the specific needs of each company. They can be modularly integrated to adapt to different workspaces and transport requirements. Some roller track models also offer additional features, such as speed control devices or sorting systems.

Lean manufacturing by elcom

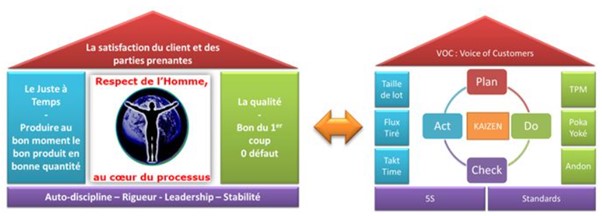

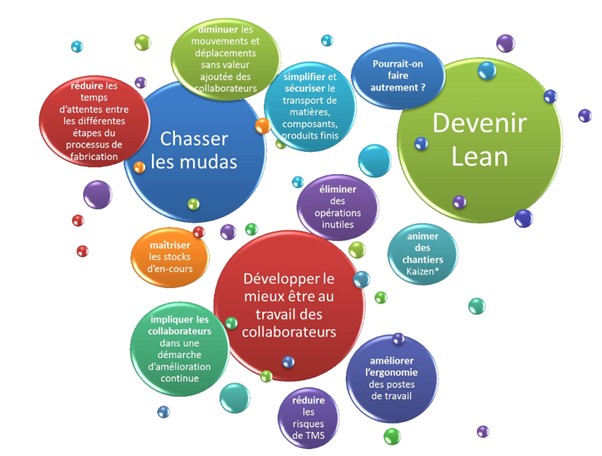

The Lean according to ELCOM is an approach that encourages constantly asking the fundamental question: “Could we do it differently?”. This philosophy aims for continuous improvement by constantly seeking ways to enhance processes. The application of Lean in the production domain, known as Lean Manufacturing, aims to reduce manufacturing costs and lead times while improving product quality and employee safety.

The roots of Lean trace back to the production system developed by Toyota in the 1950s. This concept was formalized and popularized in the late 20th century by American researchers and consultants. The term “Lean,” which translates to “thin” or “slim,” is interpreted in the Lean context as synonymous with agility and efficiency. It is about having an organization that is adapted to business challenges, without wasting energy, material, or resources, while preserving employee well-being.

For H’ELCOM, Lean is primarily a philosophy supported by specific tools. These tools are designed to identify and eliminate waste, improve processes, and foster a culture of continuous improvement within the company. Among the tools commonly used in Lean are Kaizen, 5S, pull flow, just-in-time (JIT), work cells, value stream maps, and many others.

For instance, Kaizen encourages small continuous improvements in all aspects of the organization, prompting employees to make improvement suggestions and actively participate in problem-solving. 5S is a methodology aimed at improving workplace organization and cleanliness, focusing on the elimination of unnecessary items, efficient organization of tools and materials, and standardization of procedures.

Lean according to H’ELCOM is not limited to production. It can be successfully applied in other areas, such as services, logistics, product development, and even business management. The objective is always the same: eliminate waste, optimize processes, and improve customer satisfaction.

By adopting Lean according to ELCOM, companies can benefit from numerous advantages, such as cost reduction, increased productivity, improved product and service quality, and better responsiveness to customer demands. However, it is essential to emphasize that Lean is an ongoing journey that requires long-term commitment from the entire organization.

In conclusion, Lean according to ELCOM is an approach that aims to promote continuous improvement by eliminating waste, optimizing processes, and creating a culture of efficiency within the company. It is a philosophy that relies on specific tools but also requires a mindset shift and willingness to challenge current practices. By adopting Lean, companies can achieve higher levels of performance and competitiveness.

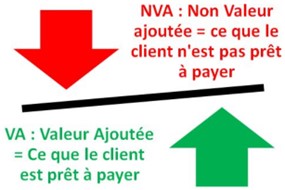

Becoming Lean according to H’ELCOM consists of reducing or even eliminating waste, inefficiencies, and variability to focus on the core essence of the company: creating value.

Value is defined by the customer: For which products, which services is the customer willing to pay?

Non-value adding activities are classified into 7 major types of waste, known as “Mudas” in Japanese.

Visual management according by elcom

Visual management plays a crucial role in implementing a Lean approach within a company. It allows information to be visualized and communicated clearly, facilitating understanding, collaboration, and continuous improvement of processes. According to Elcom, visual management can take different forms to meet the specific needs of each company.

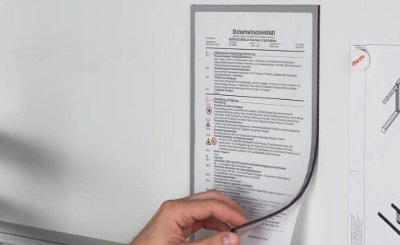

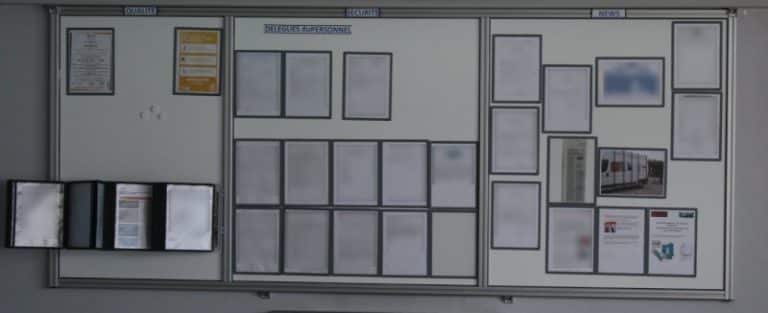

The first category of visual management proposed by Elcom is display systems. These systems allow the right information to be presented in the right place in a clear and organized manner. They can take the form of panels, boards, magnetic supports, job cards, or any other visual means. The goal is to make essential information easily accessible to all team members. For example, job cards displayed visibly enable employees to clearly understand their responsibilities and specific tasks. Safety instructions, performance indicators, or process information can also be displayed so that everyone can quickly see and understand them. These display systems promote transparency, effective communication, and team autonomy.

The second category of visual management is whiteboards. These boards are particularly suitable for working sessions, seminars, and meetings in general. They provide an interactive space where ideas, problems, action plans, and key performance indicators can be visualized and discussed in real-time. Whiteboards facilitate collaboration and engagement of all participants by allowing information to be organized in a structured way, adding annotations, making diagrams, charts, or noting progress. They thus foster creativity, problem-solving, and collective decision-making.

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.

VISUAL DISPLAY SYSTEMS

Visual display systems play a crucial role in implementing Lean principles, as they facilitate communication and information sharing in a simple and accessible way. At Elcom, we understand the importance of transparent communication and promoting team autonomy, which is why we offer a range of display systems tailored to your needs.

One of the advantages of our display systems is that they provide easy access to job cards. By placing them visibly, you provide each team member with a clear reference to their responsibilities and specific tasks. This promotes understanding and autonomy among employees, who can quickly refer to important information to carry out their daily activities.

Additionally, our display systems are designed to make it easier for you to animate your briefing points and training sessions. You can organize and display information in a structured manner, allowing your team to easily follow discussions and absorb shared knowledge. Display systems offer a powerful visual support to captivate your audience’s attention and make your presentations more impactful and effective.

Highlighting safety instructions is another important aspect of display systems. By displaying them clearly and visibly, you reinforce safety awareness within your company. Critical safety instructions are easily accessible to all team members, which helps reduce the risk of accidents and promote a proactive safety culture.

Furthermore, our display systems facilitate communication with your teams. You can use these devices to communicate important information such as updates, directives, or specific instructions in a simple and effective manner. Relevant information is presented clearly and concisely, allowing your employees to stay informed and respond quickly to changes or specific situations.

The magnetic display system

Display systems adaptable to profiles

WHITEBOARDS

Whiteboards are essential elements for any meeting, seminar, or work session. They are an indispensable management tool that allows for a practical and effective combination of utility and enjoyment. At Elcom, we understand the importance of providing modular tools that facilitate your daily tasks, and our whiteboards meet this requirement.

Our whiteboards are designed to be as modular as all of our Elcom elements. They adapt to your specific needs and allow you to customize your workspace. Whether you need a magnetic or non-magnetic whiteboard, our products offer you the possibility to write, erase, and rewrite your content in a simple and convenient way.

The surface of a whiteboard is ideal for taking notes, creating diagrams, making charts, or displaying graphs. You can easily write with dry-erase markers, then erase and make changes based on the needs of your meeting or work session. This flexibility enables you to capture ideas in real-time and collaborate interactively with your team.

Moreover, our whiteboards can be magnetic, providing an additional functionality. You can attach adhesive notes, documents, cards, or any other magnetic support to organize and structure your ideas visually. This facilitates the visualization of information and the understanding of concepts, promoting creativity and problem-solving.

Elcom whiteboards are designed to be practical and intuitive to use. They allow you to organize your ideas clearly and concisely, highlight key points, and facilitate visual communication. With our whiteboards, you can collaborate effectively, encourage participation from all members of your team, and make the most of your meetings and seminars.

LEAN EXAMPLES

Thanks to its in-depth understanding and application of Lean philosophy, principles, and tools, Elcom plays a crucial role in supporting its clients in their continuous improvement journey. Faced with numerous challenges encountered by businesses, Elcom relies on its unique range of products to offer tailored solutions. In particular, Elcom’s h’ 8 40 tubes and connectors prove to be the perfect tools for implementing a Lean approach. Their simplicity, modularity, and complementarity allow for the elimination of many forms of waste, while reducing the risk factors for musculoskeletal disorders (MSDs) and improving employee well-being in the workplace.

The integration of Elcom’s products into the production system of companies allows them to fully benefit from the advantages offered by Lean. The h’ 8 40 tubes and connectors are designed to facilitate the implementation of an efficient and flexible organization. Their user-friendly simplicity and modularity enable the quick adaptation of production flows to changes in demand, thus reducing downtime and delays. Furthermore, their complementarity allows for the design of customized structures that precisely meet the specific needs of each company.

The use of h’ 8 40 tubes and connectors from Elcom within a Lean approach contributes to waste elimination. These products enable the design of ergonomic and optimized workstations, promoting the continuous flow of operations and minimizing unnecessary movements. The modularity of the tube and connector systems also allows for rapid reconfiguration of installations to meet fluctuations in demand, avoiding overproduction and excessive inventory.

In addition to reducing waste, the use of Elcom’s products in a Lean approach contributes to improving the health and safety of employees. Factors related to the risk of musculoskeletal disorders are taken into account during the design of structures using h’ 8 40 tubes and connectors. These products allow for the creation of ergonomic workstations that encourage correct posture and reduce unnecessary physical strain. This results in a decrease in the risk of injuries and fatigue, as well as an overall improvement in well-being in the workplace.

With the Base 30 Lean production system, you transition from planning to realization, significantly increasing your productivity. Thanks to the D30 Aluminum Tube Line, you have a versatile and flexible solution that offers maximum stability with minimal assembly effort. The ease of adjustment, complement, and modification allows you to create tailor-made, cost-effective solutions that fit your specific needs. Trust in the Base 30 to optimize your production process and achieve high-performance results.