elcom

Transfer MCS

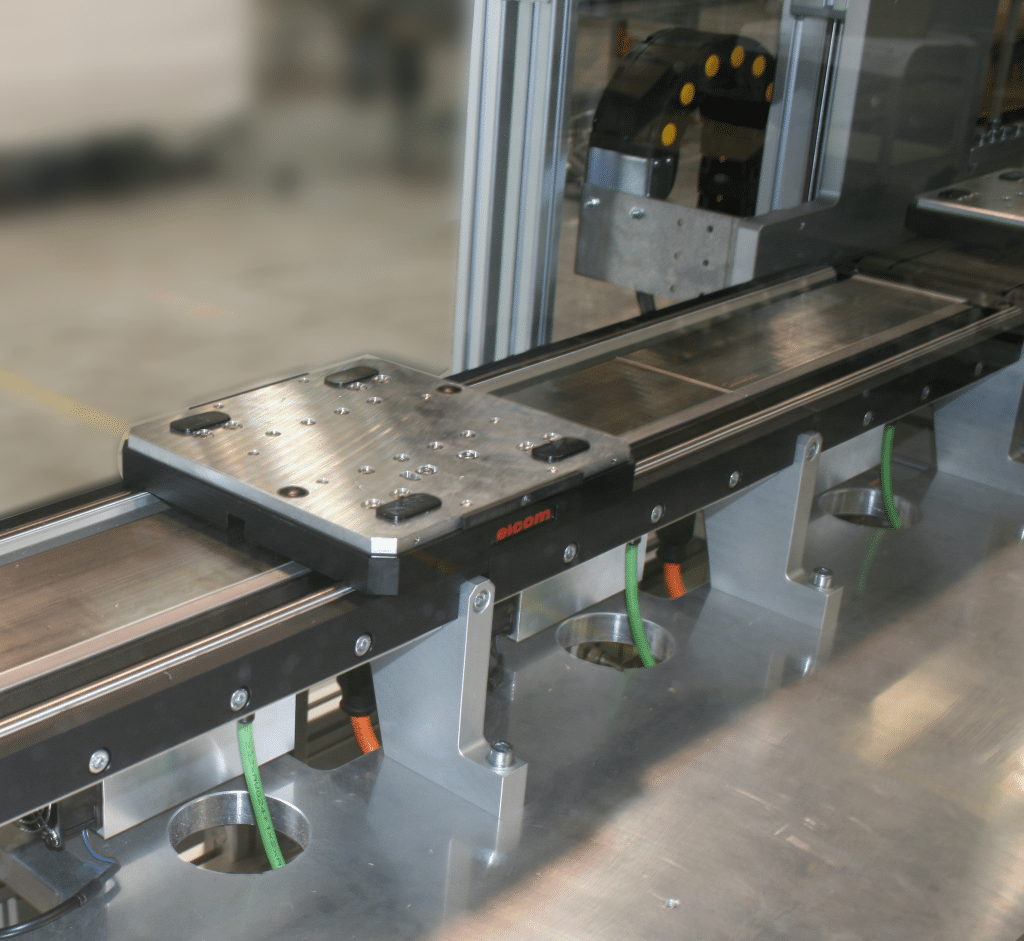

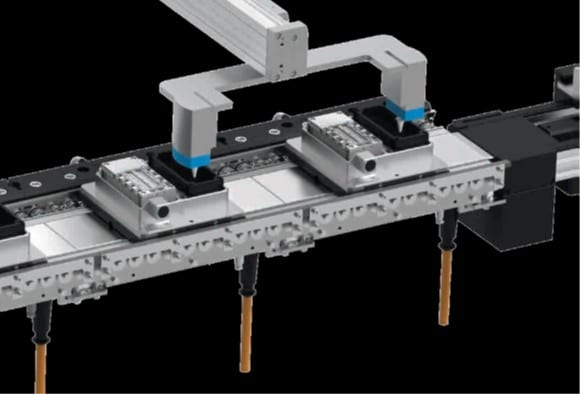

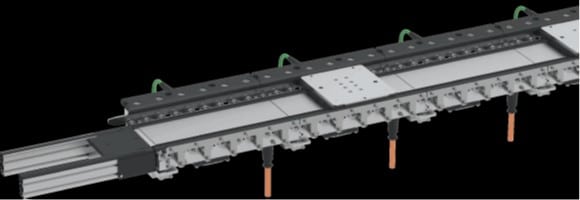

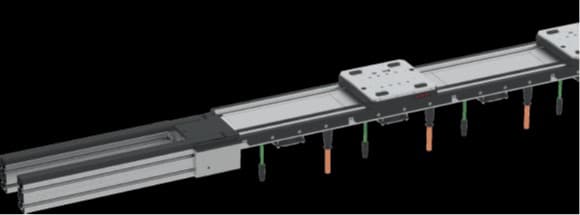

The Multi-Carrier-System (MCS) transfer is an innovative and flexible transportation system based on linear motors. Thanks to its modular structure, it can be freely configured and adapted to your specific needs. What makes MCS® unique is its ideal combination with elcom transfer systems and conveyors. For this purpose, modular sets, standardized supports, and adapted hellomoov™ guidance systems have been developed.

The utility of the MCS Transfer

This system allows the movement of your industrial parts using standardized workpiece pallets for flexible and dynamic motions. Additionally, you can customize the workpiece carrier of your choice on our standard aluminum base.

MAXIMUM MACHINE FLEXIBILITY

How do you keep up with rapidly evolving markets? How do you meet the increasingly specific needs of your customers? And how do you adapt to ever-shortening product life cycles?

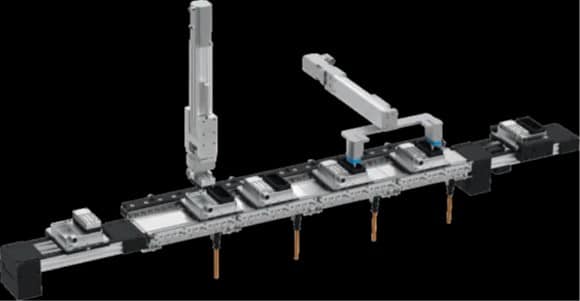

To tackle these challenges, you need solutions that offer maximum flexibility and efficiency in production processes. With the Multi-Carrier-System (MCS®) innovation, a collaborative development by Festo, Siemens, and elcom, you are on the right track. Thanks to the modular design of the MCS, it can be combined with standard transfer solutions, adding MCS® functionality where needed in the process.

Pallets can be freely introduced and removed, providing smooth acceleration and extremely precise positioning. High dynamics minimize pallet change times during the process. Siemens motion control systems enable precise management of pallet speed and position, as well as the integration of pallet movement (X) with other servo-controlled machine process movements (e.g., screwing operations or product deposition). The system is simple and quick to configure.

Adaptations can be flexibly made in the digital model, while reconfigurations and format changes are carried out with the simple push of a button.

The strengths

Flexible

• Individual control of each carrier

• Control of position, speed, acceleration, and force

Dynamic

• Acceleration up to 50 m/s²

• Speeds up to 4 m/s

• Very short transport times due to maximum dynamic response

Modular

• Modular configuration of the MCS® line

• Selection of guidance and carriers based on application requirements

• Payloads from 50 g to 10 kg

Economical

• MCS® only on stations relevant to the process

• Hybrid solution: combination with conventional transport systems

Optimized system layout and minimum changeover time for maximum productivity

A production facility with various assembly stations poses a particular challenge for product transportation. Different processing times require a combination of single and double cycles, continuous movement, high-precision positioning at screwing and testing stations, or 3D movement at a gluing station—all in one line. This is easily achievable with the Multi-Carrier-System (MCS®) in the smallest installation space and with minimal integration effort. MCS® provides you with an optimal process flow, maximizing productivity, and reducing downtime and changeover times.

The 24V Modular Transfer System (ITS) provides a significant noise reduction compared to pneumatic systems, thereby improving working conditions. Additionally, as no pneumatic network is required, it is environmentally friendly and non-polluting.

The strengths

• Maximum productivity by reducing changeover times by up to 80%

• Cost-optimized concept due to the unlimited use of conventional transfers, complemented by MCS functionality

• Optimal system layout with reduced travel length

• Optimized multi-stop function for cycle time

• Highly flexible MCS section precisely where the process demands it

The various possible solutions with the MCS transfer

Depending on your case, the modular MCS transfer provides exceptional flexibility to address various situations and specific needs. Here are some concrete examples illustrating the versatility of this innovative approach.

Synchronization of stations with different cadences on the same production line.

The MCS® allows production on a single line without mechanical segmentation or separation of sections. The optimized mechanical structure (without parallel sections with switches) saves space in the installation. A waiting position with a minimal distance is integrated into the continuous transport line. The shortest paths and the high dynamics of the pallets ensure the shortest change and stop times. The movement of individual or grouped pallets for identical stations in series can be easily assigned to (each station) through automatic addressing.

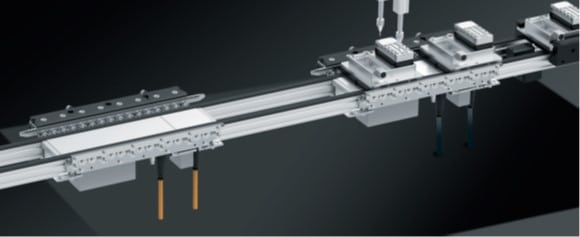

Simple and time-optimized multi-stop function within the cycle time.

The MCS® enables multiple stop positions within a minimal installation space and with the shortest travel distance – without mechanical indexing of the stop position. Even the smallest distances between screwing positions (<1 mm) can be achieved in the line without complex screwing solutions involving a third axis or additional screwing stations. The high dynamics of the conveyor and minimized downtime ensure faster synchronization. During a product change, the switch is made with a simple button press via software without any mechanical configuration change. In the case of using a Cartesian X.Y. robot, the MCS transfer replaces the X-axis and can interact with the Y-axis.

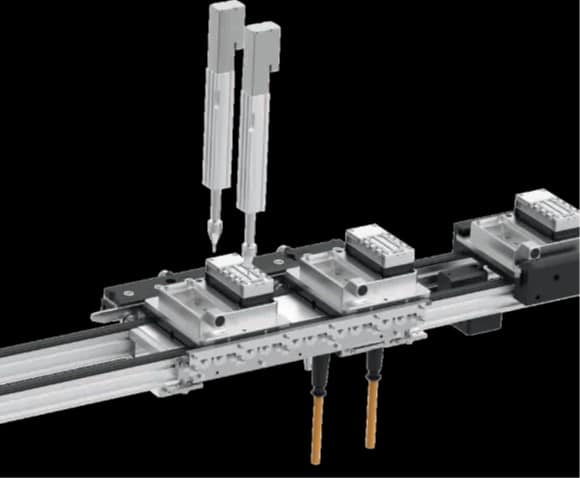

Record a process axis for 3D trajectory movements.

Due to the precise forward and backward movement (inversion) of the pallet, the MCS® serves the function of an axis. The elimination of an axis makes the dosing control more compact and cost-effective. The desired trajectory movement of the dosing head is created by the superimposed movement of the handling axes and the support. The required trajectory precision is ensured by the coordinated control of the MCS® and the dosing management.

COMBINATION OF MCS WITH THE TRANSFER TLM 1500

Transfer systems based on double-belt conveyors are standard in a wide range of industries. They transport products to various workstations on carriers. The parts remain on the pallets and can be processed directly on-site in most cases.

The TLM 1500 elcom transfer system has a modular design and offers a large number of standardized modules for different functions. These include stops and indexers, transport units, as well as lifts and other modules.

The Multi-Carrier-System MCS® is the perfect complement to the transfer system and can be precisely used where it adds the most value – for more flexible process sequences, reduced changeover times, and thus significantly higher productivity. The entry and exit between the TLM transfer system and the MCS® system are always carried out without loss of time, respecting the flow.

Key Features

• Reduction of changeover times by up to 80%

• Highly flexible MCS line

• Ideal for short-cycle applications

• Elimination of parallel processing stations

• Cost-optimized concept through the use of elcom’s modular system, complemented by MCS functionality

COMBINATION OF MCS WITH THE TLM 2000 TRANSFER

“Transfer systems based on double-belt conveyors are standard in a wide variety of industries. Products are transported to different processing stations on carrier pallets. Here, the parts remain on the pallet and can generally be processed directly on it.

The elcom TLM 2000 transfer system has a modular structure and offers a large number of standardized assemblies for various functions. These include stops and indexing units, transport units, as well as lifts and other modules.

The Multi-Carrier-System MCS® is an ideal complement to transfer systems and can be used precisely where it provides decisive added value – more flexibility in the process flow, reduced changeover times, and thus significantly higher productivity. The incoming and outgoing transfer between the transfer system and MCS® is always transparent and without interruption.”

Key Features

• Reduction of changeover times by up to 80%

• Highly flexible MCS line

• Ideal for short-cycle applications

• Elimination of parallel workstations

• Cost-optimized concept through the use of elcom’s modular system, complemented by MCS functionality

Video of transfer MCS

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.