elcom

Accessories for aluminium profiles

When assembling a modular aluminum workstation, accessories play a crucial role in enhancing the functionality, versatility, and efficiency of the workstation. Accessories are additional components or attachments that can be integrated into the workstation system to meet specific requirements and provide added convenience to the users. Here are some common roles of accessories in a modular aluminum workstation.

The range of accessories for elcom aluminum profiles

In the elcom range, you will find a variety of accessories specifically designed for modular aluminum profiles. Here is a detailed description of the examples of accessories we have available

Fixing accessories (FIXE): elcom fixing accessories, such as nuts, brackets and fixings, offer high mechanical strength. They allow precise positioning of aluminum profiles without requiring significant machining such as drilling and tapping. These components are essential to ensure a solid connection between the profiles and guarantee the stability of your structure.

Security accessories (SAFE): To secure your mechanically assembled modular aluminum constructions, elcom offers a range of accessories such as hinges, handles, latches and cable clips. These elements ensure the protection and safety of users by preventing any unwanted movement of the assembled elements.

Ergonomic accessories (ERGO): elcom understands the importance of ergonomics in the interaction between man and machine. Thus, the ERGO range offers a variety of accessories such as lighting and air intakes. These elements are designed to create an ergonomic workspace, providing a comfortable and safe environment for your employees.

Basic accessories (BASE): Elcom end caps and joint covers are among the essential basic accessories for building a robust mechanically assembled solution. These components provide an aesthetic finish and protect the ends of the aluminum profiles, thus reinforcing the assembled structure.

Assembly tools (EASY): elcom offers a complete range of assembly tools, such as threads and wrenches, to facilitate the assembly of aluminum profile solutions. These tools are designed to ensure efficient, accurate and rapid assembly, allowing workers to complete their jobs with ease and efficiency.

Lifting accessories (LIFT): The body lifts in the elcom LIFT range are specially designed to accompany the movement of the assembled parts. These accessories make it easier to lift and move aluminum members, providing increased flexibility when configuring or modifying your structure.

Movement accessories (MOOV): elcom MOOV rollers and guides are robust and solid accessories that allow fluid movement of assembled aluminum elements. These components guarantee ease of adjustment and movement, ensuring the flexibility and durability of your structure.

By combining these accessories, elcom offers a complete and diversified range that meets the specific needs of performance, safety, ergonomics, solidity and connectivity for modular constructions in aluminum profile.

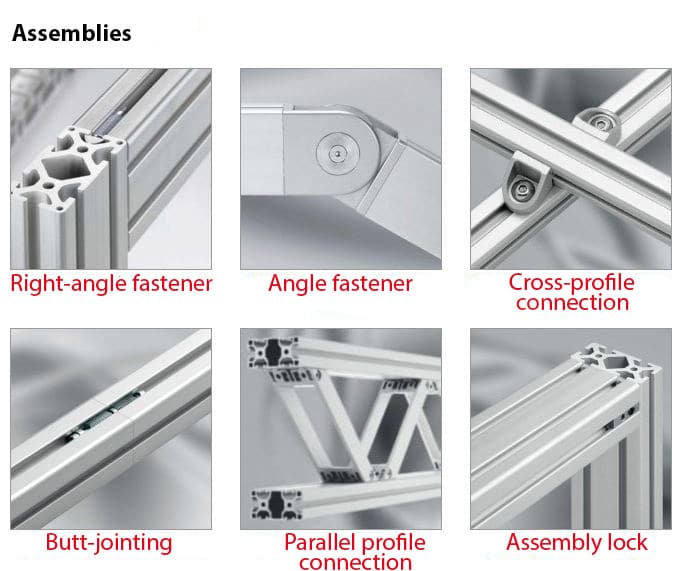

The different types of fixings for aluminum profiles

The fixings, connections, reinforcements and joints in the elcom range are designed in a clever, functional and efficient manner. These elements play a crucial role in the assembly of mechanical structures. They are made from high quality materials to ensure durability.

They are available in a variety of models to meet different needs and assembly configurations. Among the types of fixings offered, we find:

Right angle fasteners with machining(s)

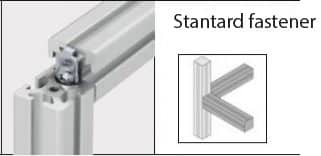

Standard fastener

The standard fastener allows a right angle assembly guaranteeing blocking power with a minimum of machining.

The standard flange ensures optimum load application, with profiles correctly positioned between them.

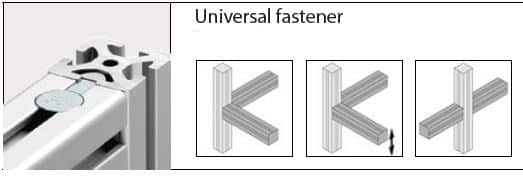

Universal fastener

The universal fastener is used to assemble all types of profiles and in all positions. The profile installed with the universal fixing can be moved along the groove.

It is specially recommended for profiles that need to be moved or fitted into an existing structure.

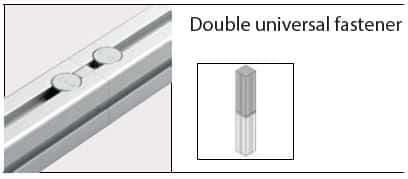

Universal fastener also exist in double universal fastener.

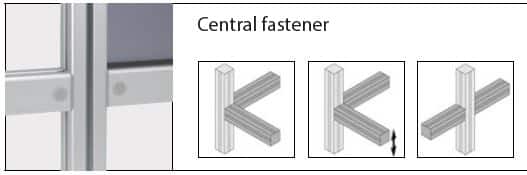

Central fastener

The central fastener connects the profiles perpendicularly and releases the grooves facing each other.

This option is advantageous when profile grooves are used to accommodate infill. Thus, special machining of the filling in the corner area becomes unnecessary.

The filling can be inserted directly into the grooves of the profiles.

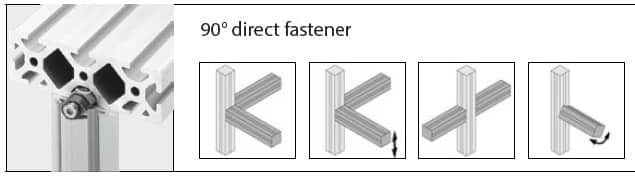

90° direct fastener

Used for fixing profiles 8 at right angles. Allows you to lock the profile at any angle. Tapping central hole M8x18.

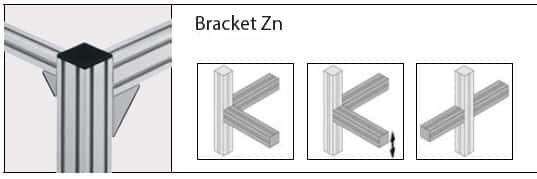

Bracket

The use of bracket kits with suitable screws and washers is recommended. Thus, the installation of the brackets is particularly simple to carry out.

In a particular application, the bracket allows you to fix trunking. The rounded inner edge prevents damage to the cables.

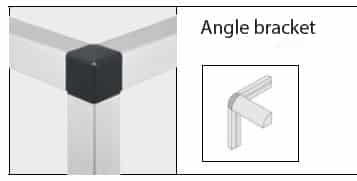

Angle bracket

The angle connection allows an aesthetic assembly of three profiles without groove.

Ideal for building tables, covers, etc…

Tapping the central hole of the profile is necessary.

Right angle fastener without machining

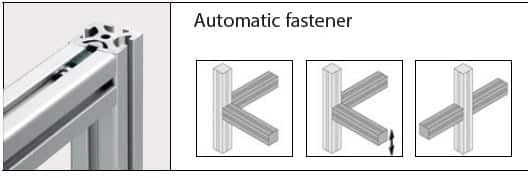

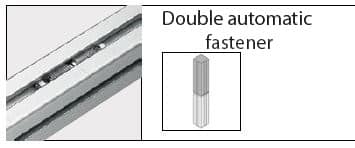

Automatic fasteners

Automatic fastener offers an innovative solution for joining profiles by adhesion.

It is quick and simple to install because no machining of the profiles is necessary. Thanks to its special shape, the fixing is put in place by simple screwing.

It is possible to put the fixings in place afterwards and move them in just a few simple steps.

Automatic bindings also exist in double automatic bindings.

Angle fasteners with machining

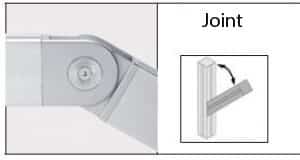

Joint

The joint allow solid assemblies with an adjustable angle from 0° to 180°.

Joint can be standard or rolling.

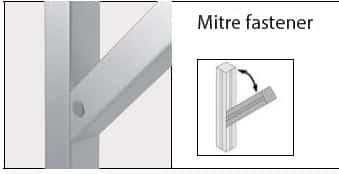

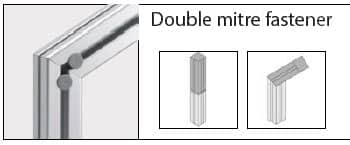

Mitre fastener

Mitre fastener allow profiles to be assembled at any angle from 30° to 90°.

The profile groove remains free to receive fillings.

Nail fasteners also come in double mitre fastener.

Angle fastener without machining

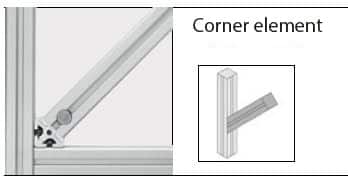

Corner element

T1 corner elements are mounted at an angle of 45° between two profiles or between them. They are fixed by Chc rounded head screws ISO 7380 and DIN 125 washers. The profile to be connected can be screwed using two universal fixings (remove the anti-twist device) and Chc rounded head screws ISO 7380.

The T2 corner elements are fixed with Chc pan head screws, universal fixings or automatic fixings and a special nut.

Fasteners for profile assemblies with machining

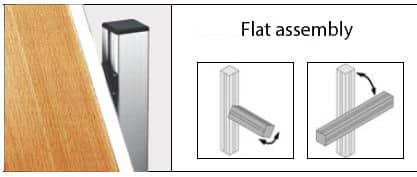

Flat assembly

Flat assembly make it possible to create a rigid connection between two profiles assembled one on top of the other.

Also used to fix the end of a profile to the grooved face of another profile.

The two components of the flat assembly are mounted between the profiles to be connected.

A tightening handle passing through the profile can be added to facilitate manual adjustment.

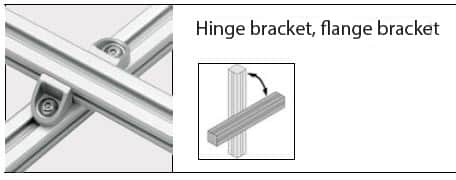

Hinge brackets and flange brackets

Hinge brackets are used to fix two profiles of the same line on top of each other.

They are generally used in pairs, a hinge bracket and a flange bracket or two flange brackets.

The flange bracket can be used in combination with the hinge bracket or with a second flange bracket to allow the fixing of two crossed profiles. Loosening the screw or handle allows rotation and movement along the two grooves.

Fasteners for profile assemblies without machining

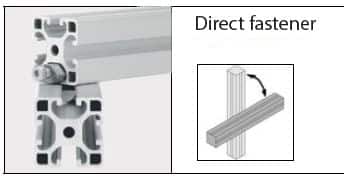

Direct fastener

Direct fastener allow robust assembly without machining of two profiles 8 coming into contact via their external surfaces. The profiles can also be placed in parallel over a certain length.

It is possible to move the two profiles in the direction of the groove.

Direct fastener is particularly suitable for assembling the profiles of the ball socket block guides with other profiles, with the possibility of movement and without machining.

Fastener for parallel profile assemblies without machining

Parallel fastener

To fix two parallel line 8 profiles at a distance of 12 mm.

Ease of use: the two half-parts of the fixing engage in the grooves of the profiles facing each other and position them. The fixation is then blocked by tightening the internal screw.

Connecting profile

Connecting profile 8 40 is machined in pairs with holes of ⌀ 11 mm (drilling distance 200 mm) for the fixing screws.

The use of cage nuts (fixed positioning and anti-twist device) allows lateral mounting. Chc screws (tightening torque M = 34 Nm) DIN 912-M10x60, M10x100 or M10x140 are used with the appropriate spacing of the connecting profiles.

Possibility of hiding the junction or the heads of screws or cage nuts in a dust-tight manner using a cover profile 32.

The elcom range

The elcom range offers a variety of clever, functional and high-performance fasteners to meet all profile assembly needs. Whether for perpendicular, crossed, parallel connections, with or without machining, or even for corrosive environments, each type of fastener is designed to ensure a solid, durable connection adapted to the specific requirements of the mechanical structure.

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.