Elcom

Automotive

As a long-standing partner of the automotive industry, vehicle manufacturers and equipment suppliers, h’elcom offers you the benefit of its expertise and experience in a wide range of areas, including : workstation ergonomics, line-side supply equipment, laboratory testing, prototyping, modeling.

Over the past forty years, we have invented and deployed the concept of modular creation.

Today, we’re enriching it with the multi-modularity of our entire profile range, so that you can design freely and without constraint.

Interoperability with our “Moovitics” range ( i.e our intelligent transitic systems) is also guaranteed.

Last but not least, we’re always ready to listen to your concerns and innovate on an ongoing basis. That’s why we created our Hellomoov’ Performance Institute.

Cost, quality, deadlines: we impose the Operational Excellence to ourselves, like it is required by our customers in the automotive industry.

As a result, our h’elcom aluminum profile solutions and applications, designed by the elcom engineering departments, have become the automotive world’s benchmark for their robustness, aesthetics and ergonomics, which are also recognized by operators.

What kind of equipement used in the automotive sector ?

In the global value chain, there are many equipments used: presses, dies, robotic welding cells, conveyors, pallet transfer systems, AGVs, robotic assembly cells, painting systems, ovens, vision and inspection systems, coordinate measuring machines…

Elcom is focused on safety (machine housing), sideline equipment (kanban cabinet) and product flow (conveyors and pallet transfer)

case study in automotive

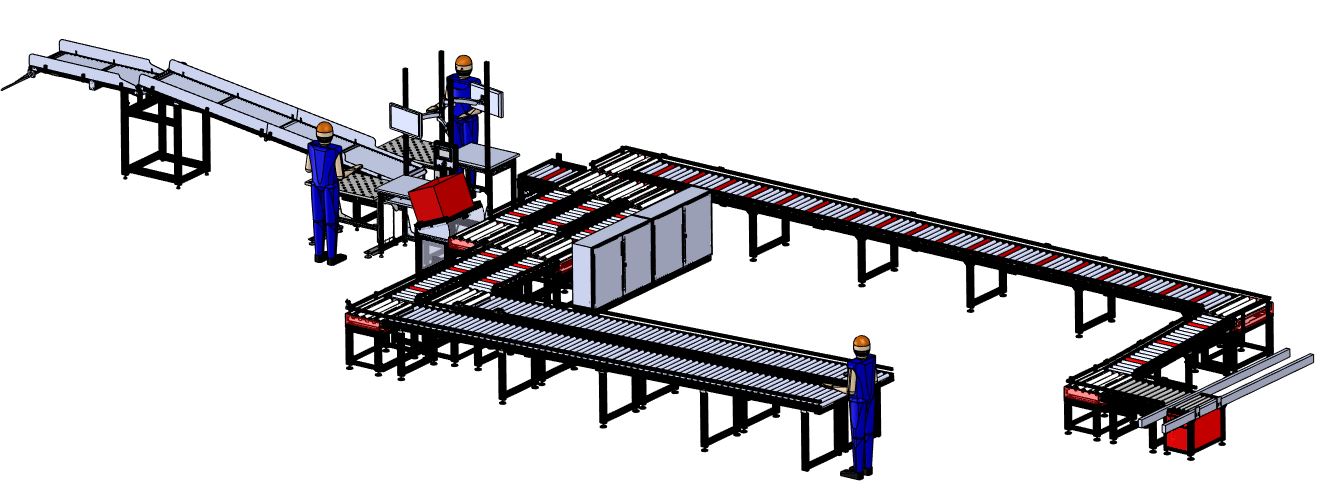

Project

One of our clients, one of the major players in the automotive industry, wanted a complete and automated line for the preparation of electronic components intended for the production and assembly of car computers.

The process was as follows: arrival of empty bins (choice of the bin according to operator needs: 2 dimensions proposed) with dispatch of the bins on 2 lanes depending on the size of the chosen bin, the bin was then scanned and weighed (if there was a weight defect, the tank did not drain) and the operator could then proceed to assemble the parts. At the end of the line, we positioned a conveyor near the operator workstation in order to evacuate the empty boxes to a cardboard bin.

Solution

To respond to this project, we created a complete and automated line.

This line is produced with TB50 Conveyors as well as motorized roller conveyors + a motorized transfer system. In addition, we have added ergonomic height-adjustable workstations with associated automation to allow employees to be in the best conditions and to be able to evacuate empty boxes to a cardboard bin.

Stäubli

Michelin

Schneider Electric

Groupe SEB

What are standards in the automotive sector ?

There is two global standards used by many industries:

ISO 9001: While not specific to the automotive sector, ISO 9001 is widely used by automotive manufacturers and suppliers. This standard focuses on general quality management principles and provides a framework for implementing a quality management system across all industries.

ISO 14001: This environmental management standard is applicable to the automotive industry, focusing on reducing the environmental impact of automotive manufacturing processes. ISO 14001 provides guidelines for implementing effective environmental management systems, resource conservation, and pollution prevention practices.

The following standards are dedicated to the automotive industry :

ISO/TS 16949: This standard, now replaced by IATF 16949, focuses on quality management systems specific to the automotive industry. It sets requirements for the design, development, production, and installation of automotive-related products. Compliance with this standard demonstrates a commitment to quality and continuous improvement in the automotive supply chain.

IATF 16949: The International Automotive Task Force (IATF) developed this standard as a replacement for ISO/TS 16949. It is a globally recognized quality management standard for the automotive industry. IATF 16949 incorporates the ISO 9001 requirements and includes additional automotive-specific requirements, emphasizing customer-specific requirements, product safety, risk management, and supplier development.

ISO 26262: This functional safety standard applies to the automotive industry, specifically focusing on the safety of electrical and electronic systems within vehicles. ISO 26262 provides guidelines for hazard analysis, risk assessment, and functional safety requirements throughout the development and production of automotive systems.

Automotive Safety Integrity Levels (ASIL): ASIL is a risk classification system defined in the ISO 26262 standard. It categorizes automotive system failures into four levels (ASIL A, B, C, and D) based on their potential impact on safety. ASIL levels guide the development of safety mechanisms and determine the necessary safety measures to mitigate risks.

Federal Motor Vehicle Safety Standards (FMVSS): In the United States, FMVSS are regulations established by the National Highway Traffic Safety Administration (NHTSA). They cover a wide range of vehicle safety aspects, including crashworthiness, occupant protection, lighting, tires, and braking systems.

REACH and RoHS: These European Union regulations are relevant to the automotive sector. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) restricts the use of hazardous substances, while RoHS (Restriction of Hazardous Substances) restricts the use of certain hazardous substances in electrical and electronic equipment, including vehicles.

OBD-II: Onboard Diagnostics II is a standard mandated in many countries, requiring vehicles to have a standardized diagnostic system. OBD-II enables vehicle technicians to access and diagnose the vehicle’s electronic systems and monitor emissions-related components.

These are just a few examples of the standards and regulations in the automotive sector. Compliance with these standards ensures safety, quality, and environmental responsibility throughout the automotive value chain. It’s important for automotive manufacturers, suppliers, and other industry stakeholders to stay up-to-date with the evolving standards and regulations applicable to their specific region and market.

Our experts are here to answer your questions, support you, and guide you through all your projects.