Elcom

Pallet transfer system - Control or orientate a product flow

Directing a flow with a conveyor-type industrial machine means adjusting the direction or orientation of objects or products transported on the conveyor. This helps ensure that items move in a specific direction or are positioned correctly for the subsequent production process.

To direct the flow, different mechanisms can be used depending on the specific needs of the application.

CAMS TLM 1000 90 degrees

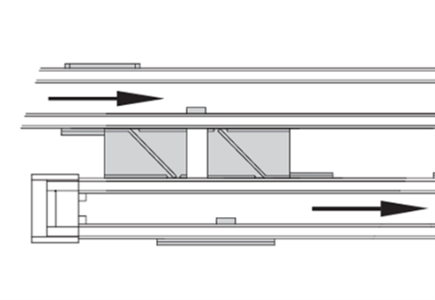

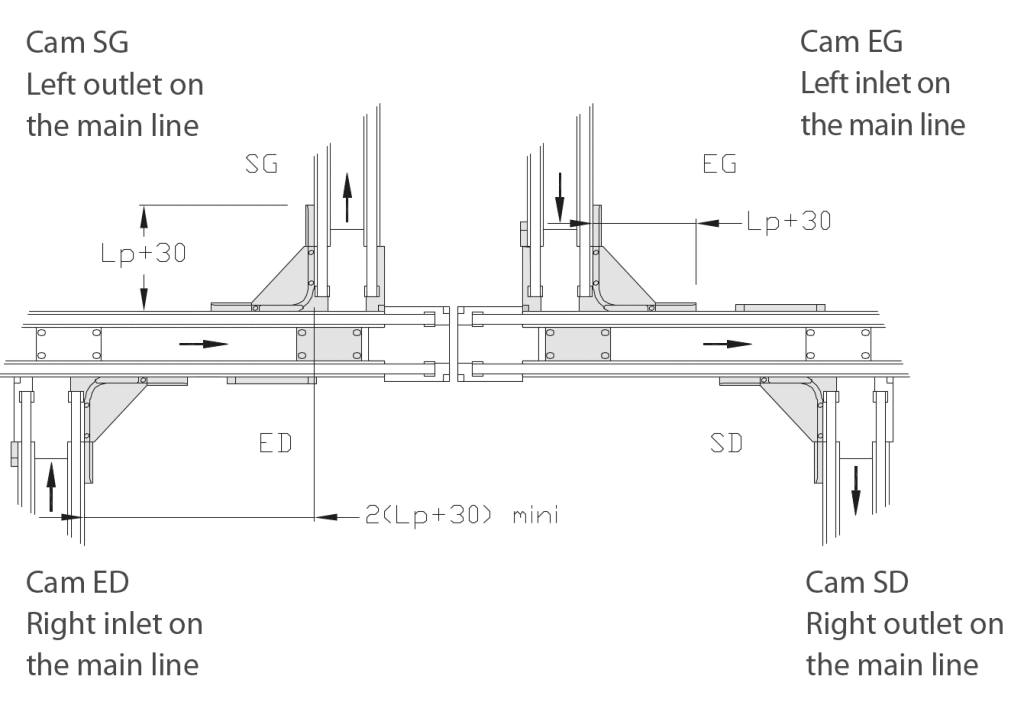

TLM 1000 90° ED, EG, SD, SG cams are devices used to direct the flow of pallets between two perpendicular transport units, without requiring automation. These cams are compatible with both smooth belt conveyor units and toothed belt conveyor units. It should be noted that these cams cannot be installed between two different transport units in standard configuration.

The operation of the TLM 1000 90° cams is based on a simple principle. The pallet to be moved is guided by the two interior pins of the cam, while the exterior pins are retracted. This ensures precise alignment of the pallet as it passes between the two perpendicular transport units.

These cams are also used for diversions, i.e. when the flow of pallets needs to be redirected to another path or process.

It is important to note that, to ensure proper operation of this system, it is essential that the vane entering the cam is not pushed by other vanes. This ensures smooth and precise movement of the paddle through the cam and prevents possible blockages or malfunctions.

CAMS TLM 1500

There are 3 types of TLM 1500 cams:

- 90° cams

- Short cams

- Double cams

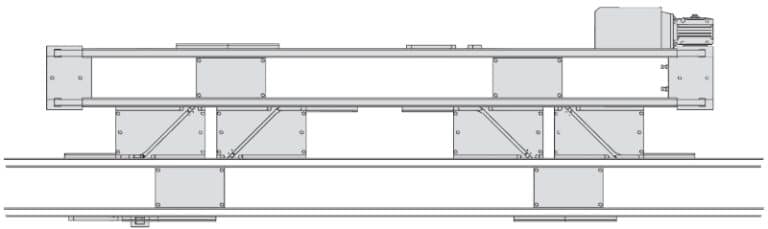

The TLM 1500 90° ED, EG, SD, SG cams allow the transfer of pallets between two perpendicular transport units without the use of automated systems. The pallet is guided by the two inner pins, while the outer pins are retracted. These cams are also used for bypasses. There is no accumulation of vanes in the cams. To ensure proper operation, it is important that the vane entering the cam is not pushed by other vanes.

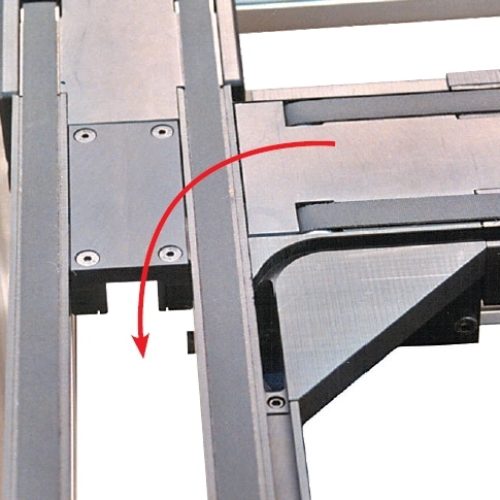

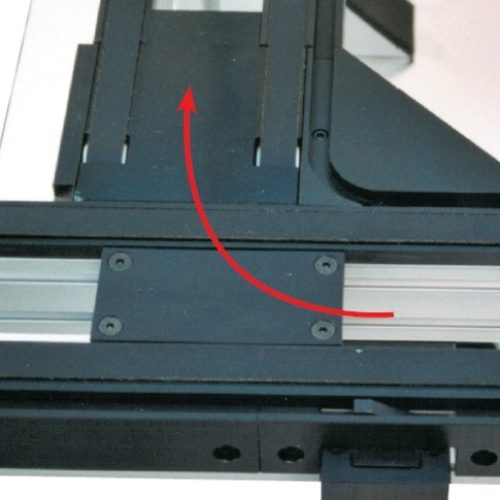

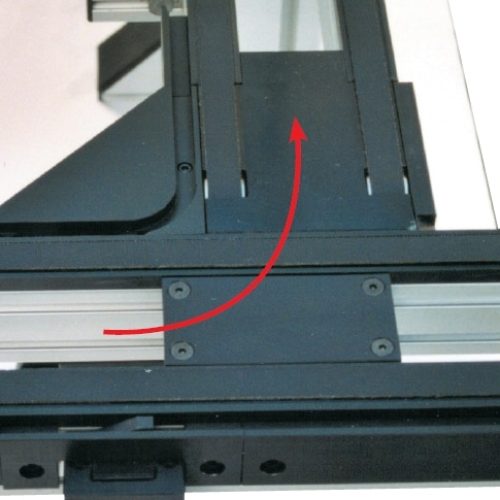

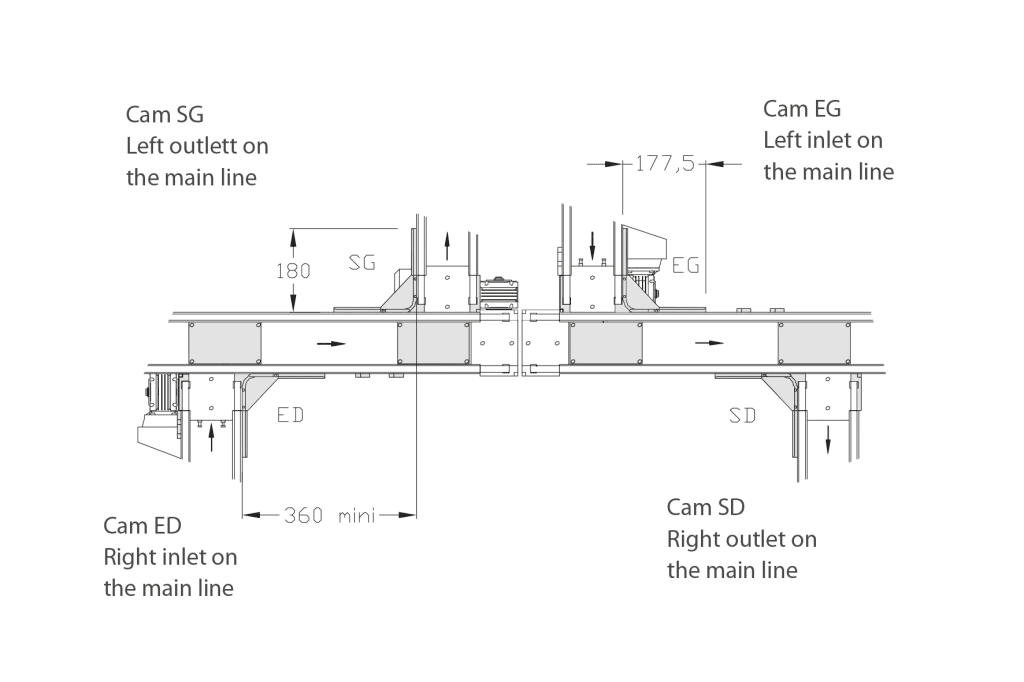

Short cams and double cams are devices that allow pallets to be diverted from a main line to a secondary line without requiring additional motorization. They offer an economical solution, with a small footprint and very simple management, which makes them an ideal choice for the creation of diversion stations.

Short cams are designed to allow rapid and efficient deviation of pallets from a main line to a secondary line. They are compact and take up less space compared to other more complex bypass solutions. Their use makes it possible to create diversion stations economically while maintaining easy management.

Double cams are similar to short cams, but they provide additional functionality by allowing the vanes to be deflected in two different directions. They can be used to create more complex and flexible diversion systems, providing the ability to direct pallets to different branch lines depending on specific needs.

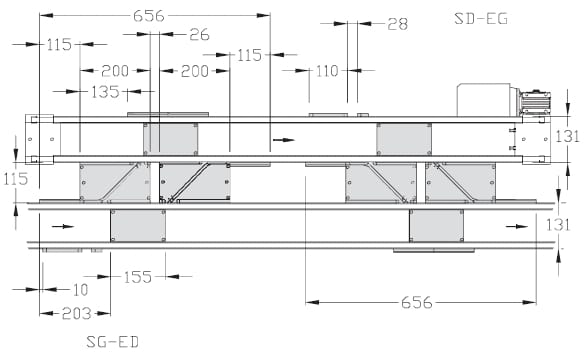

CAMS TLM 1500 90° WIDTH 150

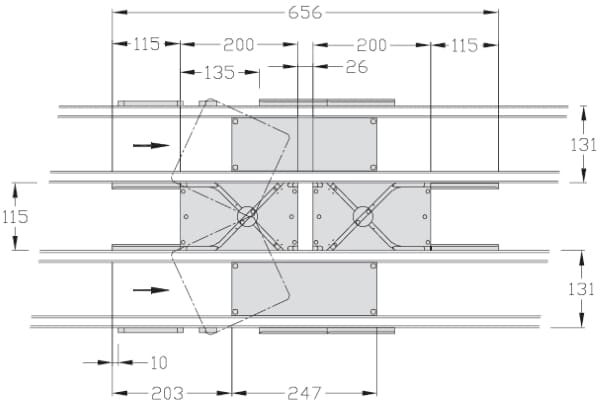

TLM 1500 SHORT CAMS SD-EG/SG-ED WIDTH 150

TLM 1500 DOUBLE WIDTH 150 CAMS

Our associated products

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.