elcom

Flat Belt conveyor C90

The 90 mm conveyor is a high-performance handling equipment, specially designed for the efficient transport of heavy and large volume parts. Made from base 8 aluminum profiles and with a width of 90 mm, this conveyor offers a robust and reliable solution for the most demanding industrial applications. Two types of 90 conveyors are available, namely the diameter 90 belt conveyor with end drive and the diameter 90 belt conveyor with end drive and motor underneath.

The design of elcom belt conveyors is based on the use of profiles from the elcom range, which gives them great modularity. Thanks to this modularity and the technical experience of their teams, elcom is able to support its customers in carrying out specific projects.

The different types of C90 belt conveyors

Belt conveyor diameter 90 with drive at the end :

The first type of conveyor 90 is the diameter 90 belt conveyor with end drive. This model offers an efficient solution for transporting heavy parts by ensuring a continuous and regular supply. Thanks to its intelligent design, this conveyor minimizes the risk of blockages and malfunctions, thus guaranteeing optimal productivity. The 90 diameter belt conveyor with end drive is particularly suitable for demanding industrial environments where reliability and strength are essential.

Belt conveyor diameter 90 with drive at the end and motor located below:

The second type of 90 conveyor we will explore is the 90 diameter belt conveyor with drive on the end and motor located underneath. This model offers the same advantages in terms of transporting heavy parts, while offering a unique configuration with the motor positioned below the conveyor belt. This arrangement allows for more efficient use of space, which is particularly advantageous in installations where space is limited. Additionally, the engine underneath provides easy access for maintenance and repairs, helping to reduce downtime and maximize equipment uptime.

The 90 mm conveyor is a wise choice for transporting heavy and large volume parts. The two types of 90 conveyors presented in this article, namely the 90 diameter belt conveyor with end drive and the 90 diameter belt conveyor with end drive and motor located below, offer reliable and efficient solutions to meet the needs of demanding industrial environments. Whether for continuous feeding or efficient use of space, these conveyors ensure optimal handling of heavy parts, thereby contributing to increased productivity and improved profitability in industrial operations.

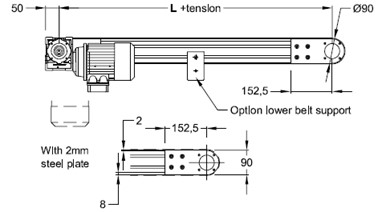

BELT CONVEYORS DIAMETER 90 END DRIVE

Technical characteristics

- Conveyor designed specifically for transporting heavy and bulky components.

- End pulley drive to ensure smooth and continuous movement.

- The pulleys are made of steel and mounted on ball bearings, ensuring increased strength and durability.

- The conveyor frame is made from aluminum profiles, offering a light and robust structure.

Dimensions

Width A: Available in different options: 500 mm, 600 mm, 700 mm, 800 mm, 1000 mm.

Length L: Variant from 500 mm to 6000 mm, providing flexibility in conveyor configuration.

Band width: Corresponds to value A reduced by 10 mm.

Belt length: Calculated using the formula Lc = (2 x L) + 300, ensuring adequate coverage of the conveyor length.

Length of the profile: Corresponds to the value L reduced by 100 mm.

Type of soles

- 8mm solid laminate.

- Stainless steel sheet.

- Galvanized steel sheet

Power supply: 230/400 V three-phase, frequency 50 Hz.

Adjustable speed: Available speed options are +/- 10% from the following values: 4 m/min, 6 m/min, 8 m/min, 10 m/min, 16 m/min, 20 m/min , 26 m/min.

Engines

Bands

- Recommended installation tension: Do not exceed 0.5% of the belt length, ensuring proper tension for optimal conveyor operation.

These technical characteristics guarantee reliable performance and adaptability to the specific needs of heavy and bulky components during transport on the 90 mm conveyor.

BELT CONVEYORS DIAMETER 90 DRIVE MOTOR END BELOW

Technical characteristics

Conveyor for heavy and bulky components:

- This conveyor is specially designed for the transport of heavy and bulky parts, offering a solution adapted to the most demanding industrial needs.

End pulley drive:

- The end pulley is driven by a toothed belt 25 mm wide, with a pitch of 10 mm. This configuration ensures efficient and reliable power transmission.

Pulleys

- The pulleys are made of steel and mounted on ball bearings, ensuring smooth rotation and long life.

- The conveyor frame is made of aluminum profiles, offering an ideal combination of lightness and strength to support heavy loads.

Frame

Dimensions

Driving diameter: 90mm, ensuring adequate driving force for the conveyor.

Width A: Available in different options: 500 mm, 600 mm, 700 mm, 800 mm, 1000 mm.

Length L: Variant from 500 mm to 6000 mm, providing flexibility in conveyor configuration.

Band width: Corresponds to value A reduced by 10 mm.

Belt Length: Calculated using the formula Lc = (2 x L) + 300, ensuring appropriate coverage of the conveyor length.

- Sole options include 8mm solid laminate, stainless steel sheet and galvanized steel sheet. These materials provide a sturdy and durable surface for transporting parts.

Types of soles

Engines

- Power supply: 230/400 V three-phase, frequency 50 Hz. A 24 VDC power supply is also available on request.

- Adjustable speed: Available speed options are +/- 10% from the following values: 4 m/min, 6 m/min, 8 m/min, 10 m/min, 16 m/min, 20 m/min , 26 m/min.

- Recommended installation tension: It is recommended to maintain a maximum tension of 0.5% of the belt length to ensure optimal operation of the conveyor.

Bands

These detailed technical characteristics of the 90 diameter belt conveyor with end drive and motor located below demonstrate its ability to efficiently handle the transport of heavy and bulky parts while providing reliable performance and adaptability to specific industry needs .

Video of Flat belt conveyor C90

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.