Elcom

Casing and framing machine

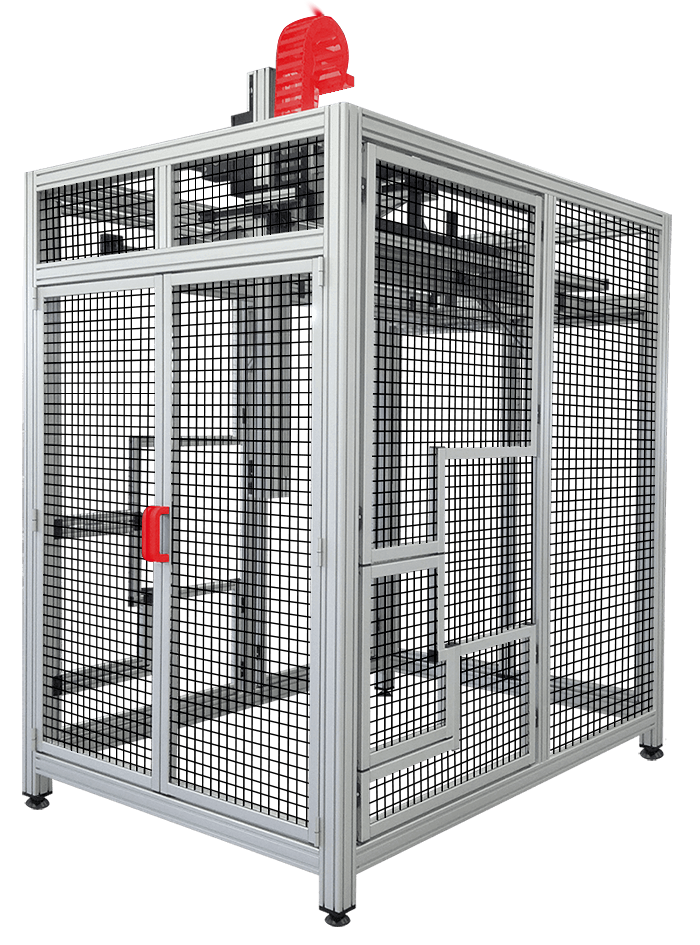

As the guarantor of machine safety and protection, encapsulation is becoming essential in many industrial companies, reducing the risk of incidents such as splinters, projections, etc.

Enclosing your machine also reduces noise pollution, improves operator safety and enhances workstation ergonomics. At Elcom, we design housings of all sizes. We offer different types of filling (opaque, translucent or wire mesh), as well as safety equipment such as switches and locking systems.

Frame and chassis

Frames and chassis made of aluminum profiles are structured around a set of crossbars and uprights that constitute the support of a machine.

Of course, one of the functions of a machine frame is to support its main active elements. It forms the basic structure of a machine, supporting mechanics, actuators – such as cylinders -, detection, coding, vision systems, as well as conveyor components and automation.

Aluminum profile frames can receive protection to ensure operators’ safety and provide a perfect cohabitation of humans and machines.

The h’elcom systems, benefiting from true modularity, allow you to evolve your aluminum profile frames as you use them with great ease (no need for painting or welding).

Protective devices compliant with the Machinery Directive 2006/42/EC can be directly connected to the machine frame or installed independently and autonomously.

Enclosure and Machine Safety

Enclosure and machine safety play a crucial role in protecting operators, preventing incidents, and enhancing working conditions in industrial environments. Enclosure refers to the construction of casings or enclosures around machines to isolate and secure them.

One of the main advantages of enclosure is the reduction of incident risks such as splinters or object projections. By enclosing the machine in a sturdy casing, potentially hazardous elements are contained inside, thus protecting operators and people working nearby. This contributes to ensuring a safer working environment.

In addition to protection against incidents, enclosure also helps reduce noise pollution. Industrial machines can generate high noise levels, which can be harmful to operators’ health if they are exposed for extended periods. By incorporating soundproofing materials into the enclosure, noise levels can be mitigated, thereby improving working conditions and workers’ health.

Moreover, enclosure contributes to improving the ergonomics of workstations. By designing suitable enclosures, accessibility and ease of use of machines can be optimized. This enables operators to perform their tasks more efficiently and comfortably, reducing fatigue and the risk of injuries related to poor posture or repetitive movements.

Regarding enclosure, different filling options are available depending on specific application needs. Opaque fillings provide maximum protection against projections and prevent visibility inside the machine. Translucent fillings allow some visibility while offering adequate protection. Mesh fillings, on the other hand, offer protection against projections while providing complete visibility of the machine.

Furthermore, it is possible to integrate additional safety equipment into the enclosure. This may include emergency stop switches, locking systems, or other safety devices intended to ensure the machine stops in case of danger or restrict access to hazardous areas.

In summary, enclosure is essential for ensuring operators’ safety and protecting machines in industrial environments. It reduces incident risks, improves working conditions by reducing noise pollution, and optimizes the ergonomics of workstations. Different filling and safety equipment options are available to meet the specific needs of each application.

Machine Frames

Machine frames, whether designed for light or heavy equipment, play a crucial role in the structure and functionality of industrial machines. These frames provide solid and durable support for the main active elements of the machine, such as mechanics, actuators (like cylinders), detection systems, coding and vision systems, as well as conveyor and automation components.

Aluminum profile frames are often used to build these structures. Aluminum profiles offer many advantages, such as their lightweight, high mechanical strength, and ease of handling. The modular design of aluminum profile systems allows for great flexibility in the construction and evolution of frames over their use.

One of the key advantages of aluminum profile frames is the possibility of adding protective devices to ensure operator safety. These devices can be integrated directly into the machine frame or installed independently and autonomously. They comply with the Machinery Directive 2006/42/EC, which defines safety standards for machines used in the European Union.

Anti-vibration fixing systems are often integrated into the frames to reduce vibrations and unwanted impacts. These special fixations help improve the stability and precision of machines by reducing disturbances caused by vibrations generated by active elements.

The applications of aluminum profile frames are diverse and not limited to industrial machines. For example, they can also be used in the construction of structures for fire vehicles, where robustness and resistance are important criteria.

By using aluminum profile systems, there is no need for welding or painting techniques, which greatly simplifies the manufacturing and modification of frames. The modularity of aluminum profiles allows for easy assembly and disassembly of different parts of the frame, facilitating modifications and future evolutions.

In summary, machine frames made of aluminum profiles offer solid and flexible support for light or heavy equipment. They allow for the integration of the main active elements of the machine, provide possibilities for adding protective devices for operator safety, and benefit from modularity that facilitates modifications and evolutions over time. Anti-vibration fixing systems also contribute to improving the stability and precision of machines.

Our associated products

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.