elcom

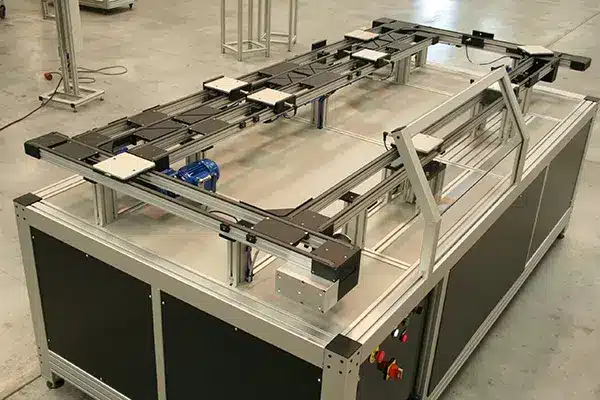

Pallet transfer system TLM 1500

The new TLM 1500 transfer system features a 150×150 mm width workpiece carrier and uses elcom’s patent with retractable pins, guides and derivation sets.

Caracteristics of TLM 1500

One of the main features of the TLM 1500 is its 150 x 150 mm pallet dimensions, which is the system standard. This pallet size provides a large enough surface area to accommodate a variety of loads, while remaining compact and easy to handle. However, it should be noted that our TLM range also offers larger pallet dimensions, ranging from 200×200 mm up to 400×400 mm, in the TLM 2000 model. Thus, users have the opportunity to choose the pallet size suitable for their specific needs.

One of the major advantages of the TLM 1500 lies in its simplicity of management and its short cam bypass system, which is both economical and efficient. By using a toothed belt as a drive mechanism, this transfer system can transport pallets with a total weight of up to 4 kg. This generous load capacity allows a wide variety of parts and products to be safely transported, providing a versatile solution for various industrial applications

This new system benefits from the advantages of our TLM 2000‘s range (workpiece carriers with dimensions from 200×200 to 400×400) with a straightforward management and a very affordable short cam derivation system.

Workpiece carriers of a total weight of 4 kg can be conveyed thanks to a timing belt drive.

GENERAL PRINCIPLE OF TLM 1500

Workpiece carriers are conveyed on two timing belts which leave necessary room for stoppers, positioning units…

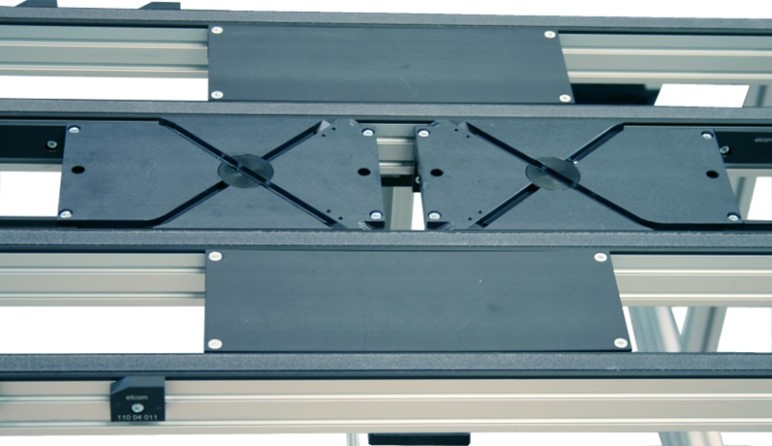

Retractable pins, located under the workpiece carrier, allow :

Guiding the workpiece carrier with 4 pins on straight sections,

Guiding the workpiece carrier round bends with 2 pins (the other being retracted).

Additional Details

The TLM 1500 is equipped with pallets measuring 150 x 150 mm, providing a suitable surface for transporting various parts and products. Each pallet can support a maximum load of 4 daN, which allows relatively light loads to be handled safely.

The system uses a notched belt to move the pallets. The travel speed can be adjusted between 12 and 16 m/min, providing flexibility in transfer operations.

The standard length of transport units in the TLM 1500 is 500 mm. However, for specific needs requiring larger dimensions, it is possible to connect several elements end to end to obtain a maximum length of 3160 mm. This allows the length of the system to be adapted according to load and accumulation requirements.

When there is a significant accumulation of pallets, it is recommended to position detectors to control this accumulation and avoid problems of overloading or blocking of the system.

It is imperative to equip all cylinders in the system with flow regulators for precise control of the movement of the vanes and to avoid jerks or shocks.

If there is a need to dismantle machines or access specific areas, it is possible to make cuts along the long lengths of the system to facilitate these operations.

the usefulness of workpiece pallets

The TLM 1500 workpiece pallets play an essential role in the precise positioning of parts during the process. They allow the attachment of supports to ensure optimal stability. The aluminum top plate guarantees positioning accuracy by maintaining the geometry of the pallet. For even greater precision, the G version of the palette is made from a ground aluminum plate. The PA base, with a low coefficient of friction, houses the pins and allows the pallet to stop precisely on the stop. Treated steel barrels are used to guarantee resistance to wear and perfect precision.

To detect pallets at different stations, metal bars are placed on each side of the pallet. This allows the movement of the pallets to be monitored and controlled precisely.

Workpiece carriers TLM 1500

Unidirectional workpiece carriers

They are perfectly compatible with a 180° swivelling.

Possibility of adding shock absorbers to limit the shock between the workpiece carriers and to reduce the noise (T).

Multidirectional workpiece carriers

For square workpiece carriers only.

They are perfectly compatible with 90°, 180° and 270° swivellings, delivered with 2 bushes and 2 additional detection bars.

The TLM 1500 offers two types of pallets: unidirectional and multidirectional. Unidirectional paddles are perfectly compatible with a 180° turnaround. It is possible to add buffers to limit shocks between the pallets and reduce noise. Multi-directional pallets, on the other hand, are only suitable for square pallets. They can be flipped to angles of 90°, 180° and 270°, and come with 2 barrels and 2 additional sensor strips to ensure optimal functionality.

CONVEYING UNIT TIMING BELT

Moving and accumulating of workpiece carriers 150×150.

The motor can be fitted either vertically or horizontally, on the right or the left side.

The use of timing belts enables to increase the carried load and facilitates the maintenance when changing belts. Belt guides are pressed into aluminum profile housing.

According to the load, longer spans can be joined end to end by straight joining.

The cuttings of conveyors allow division of the lengths, making transport and installation of the lines easier.

The installation is facilitated thanks to the use of timing belts.

Spacers have to be fitted between the profiles every 1 meter to ensure a perfect parallelism of the profiles.

TLM 2000 COMPONENTS + MODULES

SPACER

Spacers have to be fitted every 1 meter to ensure a perfect parallelism of profiles.

CAPS

Allow to protect the direct driving and the idling unit.

CAMS 90°

The cams ED, EG, SD, SG allow a perpendicular transfer of wokpiece carriers from one conveying unit to the other without automatism.

The workpiece carrier is guided by the two inner pins, the outside pins are retracted.

They are also used for derivations.

Do not accumulate the workpiece carriers in the cams.

For a good operating, the workpiece carrier coming in the cam mustn’t be pushed by other workpiece carriers.

SHORT CAMS

The short cams allow deviation of workpiece carriers from a main line to a secondary line without additional motorization.

Economical, compact and very easily managed, they are ideal to set up work stations in derivation.

DOUBLE CAMS

The double cams allow deviation of workpiece carriers from a main line to a secondary line without additional motorization.

Economical, compact and very easily managed, they are ideal to set up work stations in derivation.

DERIVATIONS

Derivations have to be used with a cam.

They allow potential divertion or not of the workpiece carrier by retraction of the pins on one side or the other of the conveyor.

The two cylinders are controlled by only one solenoid valve.

CONVEYING UNIT STAND

Support to fit conveying units on table or frame.

STOPPERS, SIMPLE-DOUBLE EFFECT

They stop workpiece carriers during processing requiring no accuracy.

They are perfectly adapted for manual work stations.

Management of workpiece carriers in order to respect conveying priorities at the end of the derivation.

Stopper simple or double effect, supplied with lateral guides, sensor bracket for detection of workpiece carriers.

The anti bouncing back is integrated in the lateral guides.

POSITIONING UNITS FOR STATION

They are settled on a table or a frame to ensure accuracy with the other surrounding elements.

A positioning set is necessary for operations requiring accuracy.

2 possibilities: simple effect stopper and double effect stopper

LIFT POSITIONING UNITS

Stop and positioning of workpiece carriers at an significant height above the conveyor.

The workpiece carrier is stopped, then elevated to a specific height, while being held by two centering pieces.

An upstream stopper is required.

2 possibilities: simple effect stopper and double effect stopper.

These Transfer Modular 1500 (TLM 1500) components play specific roles in the conveyor system, enabling precise movement of pallets, diversions and stops during necessary operations. They contribute to the flexibility, efficiency and simplified management of the transfer system.

One question ?

“Our experts are here to answer your questions, support you, and guide you through all your projects.”