Elcom

Positioning for a workbench

Positioning for a manual operation workbench involves arranging the work environment and organizing tools and materials in a way that optimizes efficiency, ergonomics, and productivity. Here are some key aspects of positioning for a manual operation workbench

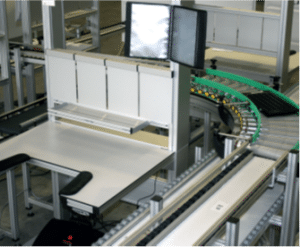

Combine transfer system and workstation

The strategic integration of pallet transfer or conveyor with workstations is a game-changer for businesses aiming to enhance efficiency and productivity. This dynamic duo not only accelerates material flow and reduces downtime but also contributes to a safer and more ergonomic work environment. As industries continue to evolve, adopting innovative solutions like the combination of conveyors or pallet transfer and workstations will undoubtedly set the stage for sustained success in an increasingly competitive market.

Prepare workspace

Ergonomics: The workbench should be designed with ergonomics in mind to ensure the comfort and safety of the workers. This includes considering factors such as the height of the work surface, appropriate lighting conditions, and proper seating if required. Ergonomic positioning helps reduce the risk of musculoskeletal injuries and promotes better workflow.

Tool Placement: Tools that are frequently used should be positioned within easy reach of the worker. This minimizes the need for excessive reaching or movement, improving productivity and reducing the risk of strain or injury. Tools can be placed on tool racks, shadow boards, or tool trays near the workbench for convenient access.

Workspace Layout: The overall layout of the workbench and surrounding workspace should be optimized for smooth and efficient workflow.

Solutions

Stoppers are used to stop or isolate the workpiece carriers. Various types of stoppers can be selected depending on the properties of the workpiece (weight, transport speed, damping requirement, etc.).

Stoppers allow pallets to be stopped during operations without positioning precision, perfectly suited to manual workstations.

Elcom stoppers allow pallets to be stopped during operations without precise positioning, and are perfectly suited to manual workstations.

They can also be used to manage pallets in order to ensure priority passage at the bypass exit.

They can be supplied with a spring to extend the stop rod in the event of an emergency stop.

The stops are supplied with a pallet presence detector support.

The pneumatically damped stopper enables pallets to be stopped during operations without positioning precision, perfectly suited to manual workstations.

Pallet management to respect passage priorities at the bypass exit.

The pneumatically damped 200 stop is used to reduce the impact of the pallet on the stop, thanks to adjustable pneumatic damping.

The damping is optimally adjusted for one pallet, but differs according to its weight.

The stop is supplied with a sensor support.

Our associated products

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.