Elcom

Sort parts (rejecting)

Sorting or rejecting products refers to the process of identifying and separating items based on specific criteria or requirements. In various industries and applications, it is often necessary to sort products based on attributes such as size, shape, weight, color, barcode, or quality, and either redirect them to different destinations or reject them from the production line.

Sorting

Sorting involves categorizing products into different groups or categories based on specific criteria. This can be done manually, where operators visually inspect and sort items, or it can be automated using technology such as sensors, cameras, or barcode readers. Automated sorting systems use algorithms and programmed logic to identify the attributes of the products and route them to the appropriate location or conveyor line.

Rejecting

Rejecting products occurs when products fail to meet certain criteria or quality standards. In such cases, the products are identified as faulty, defective, or non-compliant, and they are removed or diverted from the production line. This can be done manually by operators who identify and remove the faulty items, or it can be automated through the use of sensors, vision systems, or mechanical mechanisms. The rejected products are typically sent to a separate area for further inspection, rework, or disposal.

Elcom solutions for sorting or rejecting:

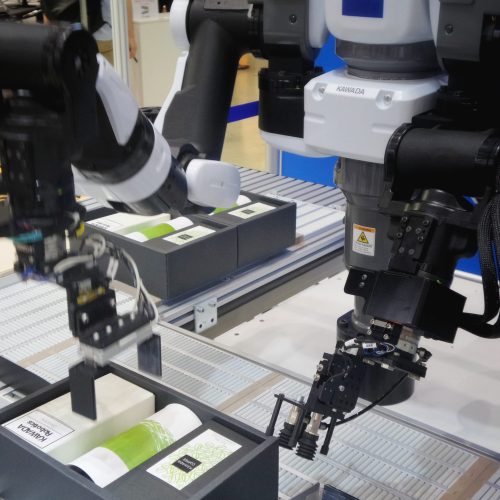

In manufacturing processes, elcom transfer systems are known for automated flow management.

The short cams (SD-EG SG-ED) and the double cams allow deviation of workpiece carriers from a main line to a secondary line without additional motorization. Economical, compact and very easily managed, they are ideal to set up workstations in derivation.

The bridge positioning units allow to rise a workpiece carrier in a station and to another workpiece carrier can flow below.

Particularly suitable for quality control station, put a pallet on a rejecting line.

Positioning accuracy +/- 1 mm.

A refocusing of workpiece carrier is required for operations which need

an important accuracy.

Our associated products

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.