Workpiece pallet transfer system configurator

Need a reliable, modular transfer system perfectly adapted to your production line?

Use our online configurator to design your own customized pallet transfer system in just a few clicks.

Dimensions, modules, options: everything can be customized to suit your industrial requirements.

View drawings, generate CAD files and get an instant quote.

A modular solution for efficient production

Workpiece pallet transfer systems enable your components to be moved precisely and safely between different workstations, whether manual or automated.

Made up of standardized modules, they offer maximum flexibility to adapt to different production configurations.

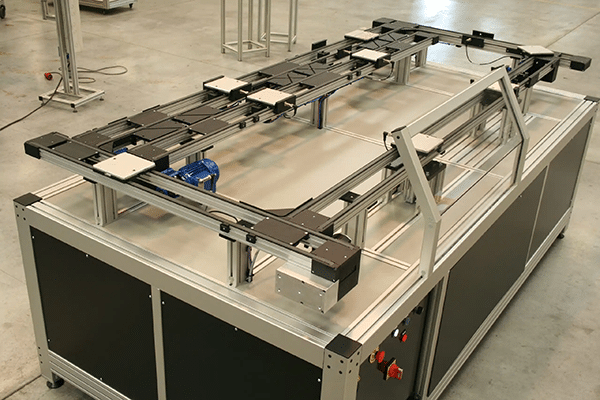

TLM 1000 pallet transfer system: reliability, precision and modularity

The TLM 1000 is a compact, modular transfer system designed to meet the requirements of modern production lines. It enables the smooth circulation of workpiece pallets between different stations, whether automatic or manual. Thanks to its flexible structure and standardized components, it can be easily integrated into any industrial environment, with a minimal footprint.

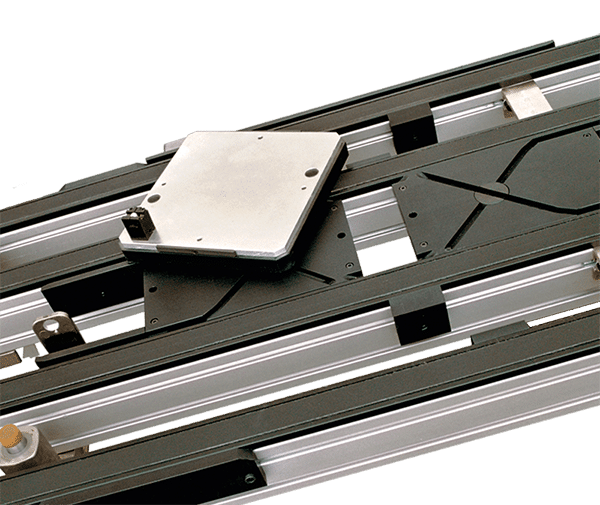

Pallets are moved by two parallel belts, available in smooth or toothed versions, depending on load and speed requirements. Retractable pins ensure precise guidance, even in curves and bypasses. The result: high stability, even when changing direction.

All TLM 1000 components are designed for use in clean, dry workshops, within a temperature range of 0 to 40°C. It guarantees excellent durability, provided that the recommendations for use are followed.

Designed to adapt to your workflow, the TLM 1000 enables parts to be managed, oriented and positioned with great precision, while ensuring a continuous production rate. It’s an ideal solution for automating internal part transport, with excellent CAD compatibility and a high level of customization via our online configurator.

Modular Linear Transfer System TLM 1500

The TLM 1500 modular linear transfer system is a flexible and efficient solution for the automated transport of small parts. Designed to meet the needs of modern industrial environments, it offers a load capacity of up to 4 kg per pallet, with dimensions of 150 x 150 mm. This model is distinguished by its toothed belt, guaranteeing optimized traction and high reliability, even at operating speeds of 12 to 16 m/min.

Thanks to its modular design, the TLM 1500 integrates perfectly into complex production lines. It allows easy customization via a configurator, enabling exact specifications to be defined according to requirements, such as bypasses, stops or indexing. This system is particularly well suited to environments where precision and flexibility are paramount. The ability to configure specific modules according to customer requirements makes it an ideal solution for a variety of applications, from assembly to the distribution of small parts.

Translated with DeepL.com (free version)

Finally, the TLM 1500 is designed for minimum maintenance, thanks to its robustness and ease of use. Its economical bypass system with short cam optimizes space while guaranteeing smooth product distribution at every stage of the manufacturing process.

TLM 2000 workpiece pallet transfer system

elcom’s TLM 2000 modular linear transfer system is an industrial solution designed to meet the need for flexibility, precision and reliability when transporting parts on workpiece pallets. It is based on the principle of linear movement by two smooth or toothed belts positioned under the pallets. Thanks to an exclusive guiding system based on retractable pins, the TLM 2000 guarantees smooth, stable circulation, even in curves, bypasses or complex transition zones.

This model is particularly suited to automated or semi-automated production lines, where repeatability and cycle optimization are essential. It supports pallet sizes ranging from 200 x 200 mm to 400 x 400 mm, covering a wide range of part formats. Each pallet is designed with an aluminum top plate, to which the part holders can be attached, and a low-friction polyamide base, guaranteeing excellent wear resistance. This modular system is compatible with manual or automatic workstations, and allows the addition of specific functions such as stops, indexing or cam-operated bypasses.

Fully configurable, the TLM 2000 integrates easily into complex production architectures. The length of the transport units can be adapted to suit the number of pallets and the load to be handled, while maintaining optimal operation. The motors can be flexibly positioned, and flow controllers installed on the cylinders enable precise control of travel speed.

Workpiece carrier pallets to suit your needs

elcom offers standard square pallets (200 x 200 mm, 300 x 300 mm, 400 x 400 mm) and rectangular pallets (200 x 250 mm, 200 x 300 mm, 300 x 400 mm). Specific dimensions can also be supplied to meet the particular requirements of each application.

Two types of pallet are available:

- U pallet: designed to move in one direction only, ideal for processes requiring constant product orientation.

- M pallet: allows rotations of 90°, 180° or 270°, suitable for applications requiring variable product orientation.

Standard modules for every stage of your process

elcom offers a complete range of standard modules to meet every specific stage of your production process:

- Press indexers: ensure precise positioning of parts for pressing operations.

- Elevator modules: enable vertical transfer of pallets between different levels of the production line.

- Turnaround modules: allow parts to be turned over for operations requiring access to different sides.

- Cycle-independent workstation solutions: optimize production flexibility by enabling parallel operations.

- Evacuation of non-conforming parts: facilitate the separation of defective parts for further processing.

Configure your online transfer system

With elcom’s online configurator, you can design your workpiece pallet transfer system in just a few clicks:

- Select your model: choose from a range of transfer systems.

- Define dimensions: enter the specific dimensions of your pallets and production line.

- Get your technical documents: download technical drawings and CAD files immediately.

- Request a quotation: send a pre-filled quotation request for a personalized offer.

This configurator is designed for industry professionals, such as design offices, integrators and maintenance managers, enabling rapid, autonomous design of your transfer solution.

Personalized support for your projects

Every industrial environment is unique. That’s why the elcom team offers you personalized support at every stage of your project. Whether you need a standard transfer system or a customized solution, our experts are on hand to design a solution perfectly suited to your technical constraints, productivity targets and budgetary requirements.

Contact us today to discuss your project and find out how our workpiece pallet transfer systems can optimize your production.

Elcom has experts to help you design your project. They’re technicians, just like you!